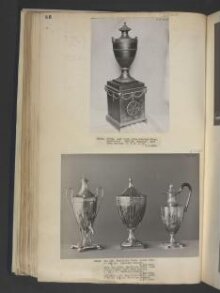

Tea-Urn

ca. 1780 (made)

| Artist/Maker | |

| Place of origin |

Object Type

The tea urn kept the water hot so that the hostess could replenish the teapot and refresh the leaves. The tea urn made its appearance in the 1760s, possibly due to the unpleasant burning qualities of most available fuels, other than the rather expensive spirits of wine. The tea kettle went rapidly out of fashion with the appearance of the charcoal-burning tea urn. Tea urns were not made of Sheffield plate until the 1780s.

People

The discovery patented by John Wadham in 1774, and incorporated in this tea urn - that a heated bar of cast iron, inserted in a sleeve and placed in an urn to keep the water hot, acted almost as efficiently as an external charcoal burner, and allowed for a more elegant design - meant that the external heater could be dispensed with.

Materials & Making

Sheffield plate was discovered in about 1742 by Thomas Boulsover, a Sheffield cutler. Boulsover's discovery was simply that copper and silver in unequal amounts, when fused, expanded together indefinitely at a uniform rate under mechanical pressure. The introduction of Sheffield plate revolutionised the plating industry, for it offered an effective, relatively cheap, supremely versatile and durable plating technique which could convincingly imitate the surface appearance of solid silver.

The tea urn kept the water hot so that the hostess could replenish the teapot and refresh the leaves. The tea urn made its appearance in the 1760s, possibly due to the unpleasant burning qualities of most available fuels, other than the rather expensive spirits of wine. The tea kettle went rapidly out of fashion with the appearance of the charcoal-burning tea urn. Tea urns were not made of Sheffield plate until the 1780s.

People

The discovery patented by John Wadham in 1774, and incorporated in this tea urn - that a heated bar of cast iron, inserted in a sleeve and placed in an urn to keep the water hot, acted almost as efficiently as an external charcoal burner, and allowed for a more elegant design - meant that the external heater could be dispensed with.

Materials & Making

Sheffield plate was discovered in about 1742 by Thomas Boulsover, a Sheffield cutler. Boulsover's discovery was simply that copper and silver in unequal amounts, when fused, expanded together indefinitely at a uniform rate under mechanical pressure. The introduction of Sheffield plate revolutionised the plating industry, for it offered an effective, relatively cheap, supremely versatile and durable plating technique which could convincingly imitate the surface appearance of solid silver.

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 2 parts.

|

| Materials and techniques | Sheffield plate (copper plated with silver) |

| Credit line | Bequeathed by Viscountess Wolseley |

| Object history | Made in England |

| Summary | Object Type The tea urn kept the water hot so that the hostess could replenish the teapot and refresh the leaves. The tea urn made its appearance in the 1760s, possibly due to the unpleasant burning qualities of most available fuels, other than the rather expensive spirits of wine. The tea kettle went rapidly out of fashion with the appearance of the charcoal-burning tea urn. Tea urns were not made of Sheffield plate until the 1780s. People The discovery patented by John Wadham in 1774, and incorporated in this tea urn - that a heated bar of cast iron, inserted in a sleeve and placed in an urn to keep the water hot, acted almost as efficiently as an external charcoal burner, and allowed for a more elegant design - meant that the external heater could be dispensed with. Materials & Making Sheffield plate was discovered in about 1742 by Thomas Boulsover, a Sheffield cutler. Boulsover's discovery was simply that copper and silver in unequal amounts, when fused, expanded together indefinitely at a uniform rate under mechanical pressure. The introduction of Sheffield plate revolutionised the plating industry, for it offered an effective, relatively cheap, supremely versatile and durable plating technique which could convincingly imitate the surface appearance of solid silver. |

| Collection | |

| Accession number | M.131-1920 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | March 27, 2003 |

| Record URL |

Download as: JSONIIIF Manifest