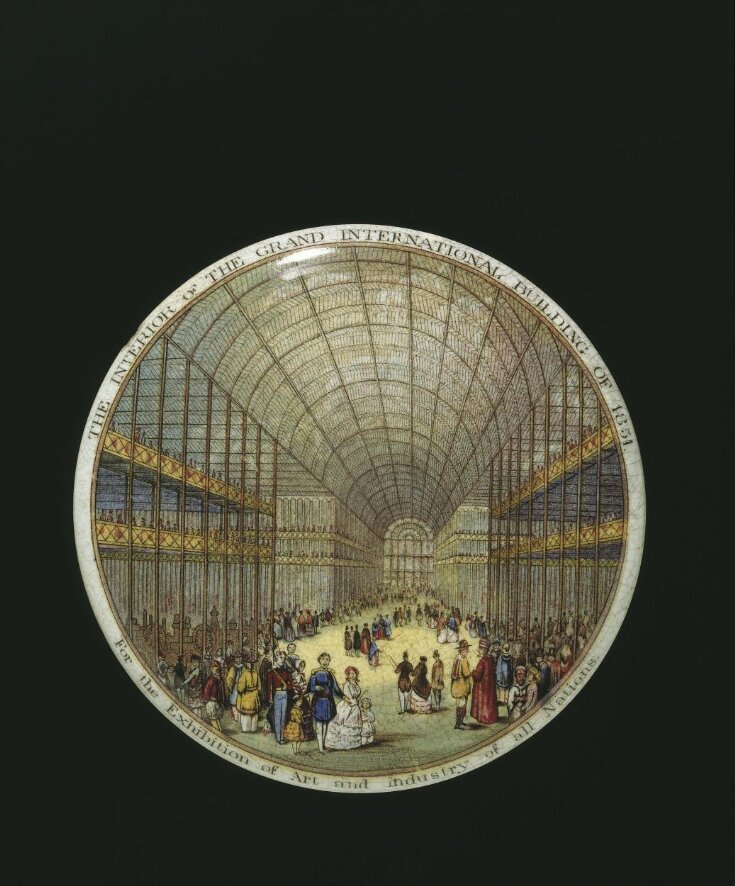

Pot Lid

1851 (made)

| Artist/Maker | |

| Place of origin |

Object Type

This Great Exhibition souvenir was a lid made by T.J. & J. Mayer for Crosse & Blackwell, of 21, Soho Square, who registered it in 1850 to ensure their competitors did not use the design. The pots for which this lid was made would have contained Crosse & Blackwell's potted meats or anchovy paste. Other firms also made pot lids, the finest being produced between 1850 and 1870.

People

Thomas, Joseph and John Mayer of Dale Hall Pottery, Longport, Burslem, were brothers from a famous Staffordshire family of master potters whose business was established in the 1780s. The Mayer brothers were awarded a prize medal at the Great Exhibition where their stand displayed various designs for meat pots, printed in underglaze colours. Mayers also produced two other views of the Exhibition. They eventually became the second largest manufacturer of colour transfer-printed lids, but made other useful goods as well, and had a thriving export trade with America.

Materials & Making

The firm of F.&R. Pratt & Co. of Lane Delph, Fenton, are thought to have been the earliest exponents of full underglaze colour-printing, though Mayers were quick to follow. An image was produced by engraving at least four different copper printing-plates, one to load with black ink, and the others with a single colour each. The coloured ink from the engraved grooves on the first plate was pressed onto dampened potter's tissue paper, which was in turn applied to the unglazed earthenware and rubbed on with a flannel boss. The tissue was floated off in water, leaving the oily ink on the pottery. After 24 hours' drying time, the next colour was applied on top, and so on, finishing with black or brown, which when accuragtely aligned, completed the image.It was only in the 1840s that suitable printing inks and paper were developed for this process.

This Great Exhibition souvenir was a lid made by T.J. & J. Mayer for Crosse & Blackwell, of 21, Soho Square, who registered it in 1850 to ensure their competitors did not use the design. The pots for which this lid was made would have contained Crosse & Blackwell's potted meats or anchovy paste. Other firms also made pot lids, the finest being produced between 1850 and 1870.

People

Thomas, Joseph and John Mayer of Dale Hall Pottery, Longport, Burslem, were brothers from a famous Staffordshire family of master potters whose business was established in the 1780s. The Mayer brothers were awarded a prize medal at the Great Exhibition where their stand displayed various designs for meat pots, printed in underglaze colours. Mayers also produced two other views of the Exhibition. They eventually became the second largest manufacturer of colour transfer-printed lids, but made other useful goods as well, and had a thriving export trade with America.

Materials & Making

The firm of F.&R. Pratt & Co. of Lane Delph, Fenton, are thought to have been the earliest exponents of full underglaze colour-printing, though Mayers were quick to follow. An image was produced by engraving at least four different copper printing-plates, one to load with black ink, and the others with a single colour each. The coloured ink from the engraved grooves on the first plate was pressed onto dampened potter's tissue paper, which was in turn applied to the unglazed earthenware and rubbed on with a flannel boss. The tissue was floated off in water, leaving the oily ink on the pottery. After 24 hours' drying time, the next colour was applied on top, and so on, finishing with black or brown, which when accuragtely aligned, completed the image.It was only in the 1840s that suitable printing inks and paper were developed for this process.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Earthenware, transfer-printed |

| Brief description | Earthenware, transfer-printed with a view of the interior of the Crystal Palace which housed the Great Exhibition of 1851 |

| Physical description | Earthenware pot lid transfer-printed with an interior view of the Crystal Palace, with inscription running around the image |

| Dimensions |

|

| Marks and inscriptions | 'THE INTERIOR OF THE GRAND INTERNATIONAL BUILDING OF 1851. For the Exhibition of Art and Industry of all Nations', printed in black |

| Gallery label |

|

| Credit line | Given by Mrs Eric Hervey |

| Object history | Made by T.J. & J.Mayer, Dale Hall Pottery, Burslem, Staffordshire. From a group of Crystal Palace memorabilia which belonged to Gerald Smedley Hervey, MBE. |

| Historical context | Such lids were for pots often designed to contain meat or fish pastes |

| Subject depicted | |

| Summary | Object Type This Great Exhibition souvenir was a lid made by T.J. & J. Mayer for Crosse & Blackwell, of 21, Soho Square, who registered it in 1850 to ensure their competitors did not use the design. The pots for which this lid was made would have contained Crosse & Blackwell's potted meats or anchovy paste. Other firms also made pot lids, the finest being produced between 1850 and 1870. People Thomas, Joseph and John Mayer of Dale Hall Pottery, Longport, Burslem, were brothers from a famous Staffordshire family of master potters whose business was established in the 1780s. The Mayer brothers were awarded a prize medal at the Great Exhibition where their stand displayed various designs for meat pots, printed in underglaze colours. Mayers also produced two other views of the Exhibition. They eventually became the second largest manufacturer of colour transfer-printed lids, but made other useful goods as well, and had a thriving export trade with America. Materials & Making The firm of F.&R. Pratt & Co. of Lane Delph, Fenton, are thought to have been the earliest exponents of full underglaze colour-printing, though Mayers were quick to follow. An image was produced by engraving at least four different copper printing-plates, one to load with black ink, and the others with a single colour each. The coloured ink from the engraved grooves on the first plate was pressed onto dampened potter's tissue paper, which was in turn applied to the unglazed earthenware and rubbed on with a flannel boss. The tissue was floated off in water, leaving the oily ink on the pottery. After 24 hours' drying time, the next colour was applied on top, and so on, finishing with black or brown, which when accuragtely aligned, completed the image.It was only in the 1840s that suitable printing inks and paper were developed for this process. |

| Collection | |

| Accession number | CIRC.789-1969 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | March 27, 2003 |

| Record URL |

Download as: JSONIIIF Manifest