Teapot

1740-1750 (made)

| Artist/Maker | |

| Place of origin |

Object Type

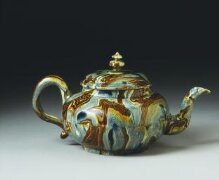

Earthenware teapots of the mid-18th century were invariably small, the two common sizes being listed in contemporary bills as for one dish (meaning one cup) or two. This example is unusual in being squat, of a form more usually found in the 1730s and 1740s standing on three applied moulded legs.

Materials & Making

With the rising popularity of Staffordshire teawares, from about 1740 various new decorative techniques were developed. Applied vine-leaf ornament, splashed oxide glazes, shiny black glazes with unfired gilding and many other variations on these themes were tried. One of the most successful was agate ware, made from sheets of coloured, cut and rolled clays - much like the millefiore glass technique. An infinite range of designs could be made, some naturalistic, others geometric; but the limiting factor, from a manufacturing point of view, was that the patterns would have been distorted by throwing on a wheel, so that normally vessels could only be built up from pressed sections. This teapot, which clearly shows the joint around the belly where the two pressed hemispheres were joined together, perfectly demonstrates the difficulty of making seamless joints. One solution was to make the agate pattern so intricate that joints were effectively disguised. Another was simply to make square slab-sided teapots with all the joints on the corners. Agate ware was expensive to make and had become obsolete by about 1760.

Earthenware teapots of the mid-18th century were invariably small, the two common sizes being listed in contemporary bills as for one dish (meaning one cup) or two. This example is unusual in being squat, of a form more usually found in the 1730s and 1740s standing on three applied moulded legs.

Materials & Making

With the rising popularity of Staffordshire teawares, from about 1740 various new decorative techniques were developed. Applied vine-leaf ornament, splashed oxide glazes, shiny black glazes with unfired gilding and many other variations on these themes were tried. One of the most successful was agate ware, made from sheets of coloured, cut and rolled clays - much like the millefiore glass technique. An infinite range of designs could be made, some naturalistic, others geometric; but the limiting factor, from a manufacturing point of view, was that the patterns would have been distorted by throwing on a wheel, so that normally vessels could only be built up from pressed sections. This teapot, which clearly shows the joint around the belly where the two pressed hemispheres were joined together, perfectly demonstrates the difficulty of making seamless joints. One solution was to make the agate pattern so intricate that joints were effectively disguised. Another was simply to make square slab-sided teapots with all the joints on the corners. Agate ware was expensive to make and had become obsolete by about 1760.

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 2 parts.

|

| Materials and techniques | Solid agate ware, with lead glaze |

| Brief description | 'Agate-ware' Teapot, Staffordshire, 1740-1750 |

| Dimensions |

|

| Gallery label |

|

| Credit line | Bought from the Haliburton Collection |

| Summary | Object Type Earthenware teapots of the mid-18th century were invariably small, the two common sizes being listed in contemporary bills as for one dish (meaning one cup) or two. This example is unusual in being squat, of a form more usually found in the 1730s and 1740s standing on three applied moulded legs. Materials & Making With the rising popularity of Staffordshire teawares, from about 1740 various new decorative techniques were developed. Applied vine-leaf ornament, splashed oxide glazes, shiny black glazes with unfired gilding and many other variations on these themes were tried. One of the most successful was agate ware, made from sheets of coloured, cut and rolled clays - much like the millefiore glass technique. An infinite range of designs could be made, some naturalistic, others geometric; but the limiting factor, from a manufacturing point of view, was that the patterns would have been distorted by throwing on a wheel, so that normally vessels could only be built up from pressed sections. This teapot, which clearly shows the joint around the belly where the two pressed hemispheres were joined together, perfectly demonstrates the difficulty of making seamless joints. One solution was to make the agate pattern so intricate that joints were effectively disguised. Another was simply to make square slab-sided teapots with all the joints on the corners. Agate ware was expensive to make and had become obsolete by about 1760. |

| Collection | |

| Accession number | 151:1, 2-1874 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | March 27, 2003 |

| Record URL |

Download as: JSONIIIF Manifest