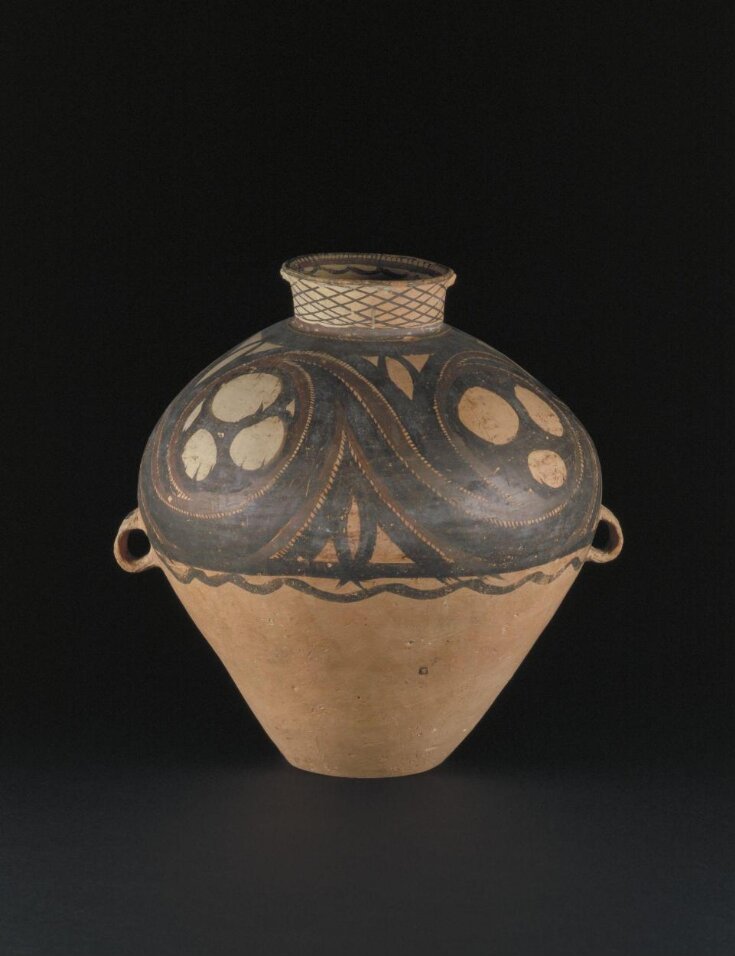

Jar

ca. 2600 BC-2300 BC (made)

| Artist/Maker | |

| Place of origin |

This large jar is of a type used for storage and in burials, as examples have been found containing remains of food and children's bones. Like many Neolithic pots from Gansu province in north-western China, the upper part is boldly painted with a dynamic spiral pattern - which probably originally had some ritual or symbolic meaning - and it is made from loess, deposits of which are found throughout the northern part of the country. True loess is a wind-borne dust, derived mainly from the mechanical weathering of igneous rocks (those formed from magma or lava). Loess deposits become increasing fine the further they are blown. Wares made from loess may be red, buff, grey or black, depending on the conditions in which they were fired, and are fine in texture.

The jar was made by the coiling method, a basic forming technique found worldwide. This involved building up the vessel from the bottom with rolls of clay strips, pinching and smoothing them down, thus controlling the growth of the vessel's shape. After finishing by beating and scraping, and applying the handles, the jar would have been fired in a relatively sophisticated kiln, in which the fire was separated from and situated underneath the chamber containing the pots. An updraught system carried the heat of the fire up to a channel to bake the wares without damaging them. Temperatures of up to 1,020°C were already achieved at this early time. Finally the jar was painted in earth pigments and burnished, to smooth and seal the surface.

The jar was made by the coiling method, a basic forming technique found worldwide. This involved building up the vessel from the bottom with rolls of clay strips, pinching and smoothing them down, thus controlling the growth of the vessel's shape. After finishing by beating and scraping, and applying the handles, the jar would have been fired in a relatively sophisticated kiln, in which the fire was separated from and situated underneath the chamber containing the pots. An updraught system carried the heat of the fire up to a channel to bake the wares without damaging them. Temperatures of up to 1,020°C were already achieved at this early time. Finally the jar was painted in earth pigments and burnished, to smooth and seal the surface.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Earthenware decorated with unfired pigments |

| Brief description | Earthenware burial jar, coil built and decorated with unfired pigments, Gansu, Majiayao culture, Banshan phase, ca. 2600-2300 BC |

| Physical description | Earthenware jar with globular body, short neck and two grips at the sides, decorated with spiral patterns on the shoulder and hatched motif round the neck |

| Dimensions |

|

| Style | |

| Gallery label |

|

| Object history | Bought from S. Segredakis, Paris |

| Subject depicted | |

| Summary | This large jar is of a type used for storage and in burials, as examples have been found containing remains of food and children's bones. Like many Neolithic pots from Gansu province in north-western China, the upper part is boldly painted with a dynamic spiral pattern - which probably originally had some ritual or symbolic meaning - and it is made from loess, deposits of which are found throughout the northern part of the country. True loess is a wind-borne dust, derived mainly from the mechanical weathering of igneous rocks (those formed from magma or lava). Loess deposits become increasing fine the further they are blown. Wares made from loess may be red, buff, grey or black, depending on the conditions in which they were fired, and are fine in texture. The jar was made by the coiling method, a basic forming technique found worldwide. This involved building up the vessel from the bottom with rolls of clay strips, pinching and smoothing them down, thus controlling the growth of the vessel's shape. After finishing by beating and scraping, and applying the handles, the jar would have been fired in a relatively sophisticated kiln, in which the fire was separated from and situated underneath the chamber containing the pots. An updraught system carried the heat of the fire up to a channel to bake the wares without damaging them. Temperatures of up to 1,020°C were already achieved at this early time. Finally the jar was painted in earth pigments and burnished, to smooth and seal the surface. |

| Bibliographic reference | Liefkes, Reino and Hilary Young (eds.) Masterpieces of World Ceramics in the Victoria and Albert Museum. London: V&A Publishing, 2008

pp. 20-21 |

| Collection | |

| Accession number | C.286-1938 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | January 17, 2003 |

| Record URL |

Download as: JSONIIIF Manifest