Vase

ca. 1850 (made)

| Artist/Maker | |

| Place of origin |

Object Type

This trumpet-shaped vase is a purely decorative object, designed to impress. It seeks attention with its silvery surface, and the use of ogee-shaped arches suggests a slightly adventurous exotic taste on the part of its owner. The method of making double-walled silvered glass was complex and made more so by the introduction of coloured glass.

Materials & Making

The process of making double-walled silvered glass was patented by Edward Varnish and Frederick Hale Thompson in 1849. A number of glassworks, such as that of James Powell & Sons of Whitefriars, London, made the blanks. A stemmed vase or goblet shape was formed, with the glass-blower stopping short of opening out the mouth. Instead, the top of the vase, still sealed as a bubble-shape, was reheated and 'dropped' inwards to form a double-walled interior. This plain, undecorated vase was then supplied to E. Varnish & Co., where it was filled between the walls from the foot end with a solution of silver nitrate and glucose (in the form of grape juice). The final stage was to seal the hole in the foot with a metal disc, in this example marked for Varnish's Patent.

Time

The silvered glass exhibited by E. Varnish & Co. fascinated commentators on the 1851 Great Exhibition. Varnish's salvers, vases, globes and goblets were bold in size and presentation, using non-tarnishing silver, ornamented with coloured casing, cutting and engraving. The process 'added a richness and beauty of colouring to that material of which few could deem it capable of receiving' (Illustrated London News).

This trumpet-shaped vase is a purely decorative object, designed to impress. It seeks attention with its silvery surface, and the use of ogee-shaped arches suggests a slightly adventurous exotic taste on the part of its owner. The method of making double-walled silvered glass was complex and made more so by the introduction of coloured glass.

Materials & Making

The process of making double-walled silvered glass was patented by Edward Varnish and Frederick Hale Thompson in 1849. A number of glassworks, such as that of James Powell & Sons of Whitefriars, London, made the blanks. A stemmed vase or goblet shape was formed, with the glass-blower stopping short of opening out the mouth. Instead, the top of the vase, still sealed as a bubble-shape, was reheated and 'dropped' inwards to form a double-walled interior. This plain, undecorated vase was then supplied to E. Varnish & Co., where it was filled between the walls from the foot end with a solution of silver nitrate and glucose (in the form of grape juice). The final stage was to seal the hole in the foot with a metal disc, in this example marked for Varnish's Patent.

Time

The silvered glass exhibited by E. Varnish & Co. fascinated commentators on the 1851 Great Exhibition. Varnish's salvers, vases, globes and goblets were bold in size and presentation, using non-tarnishing silver, ornamented with coloured casing, cutting and engraving. The process 'added a richness and beauty of colouring to that material of which few could deem it capable of receiving' (Illustrated London News).

Object details

| Categories | |

| Object type | |

| Materials and techniques | Ruby and white glass, silvered |

| Brief description | Vase, England (probably London), possibly made by J. Powell and Sons under the patent of F. Hale Thomson and E.Varnish, 1849-1860 |

| Dimensions |

|

| Style | |

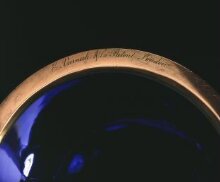

| Marks and inscriptions | 'E. Varnish & Co. Patent London' inscribed on the metal rim and on an inserted metal plug in the base Note Makers's mark |

| Gallery label |

|

| Object history | Probably made in London by James Powell & Sons |

| Production | E. Varnish and F. Hale Thomson patented the silvering process used in the manufacture of this vase. |

| Summary | Object Type This trumpet-shaped vase is a purely decorative object, designed to impress. It seeks attention with its silvery surface, and the use of ogee-shaped arches suggests a slightly adventurous exotic taste on the part of its owner. The method of making double-walled silvered glass was complex and made more so by the introduction of coloured glass. Materials & Making The process of making double-walled silvered glass was patented by Edward Varnish and Frederick Hale Thompson in 1849. A number of glassworks, such as that of James Powell & Sons of Whitefriars, London, made the blanks. A stemmed vase or goblet shape was formed, with the glass-blower stopping short of opening out the mouth. Instead, the top of the vase, still sealed as a bubble-shape, was reheated and 'dropped' inwards to form a double-walled interior. This plain, undecorated vase was then supplied to E. Varnish & Co., where it was filled between the walls from the foot end with a solution of silver nitrate and glucose (in the form of grape juice). The final stage was to seal the hole in the foot with a metal disc, in this example marked for Varnish's Patent. Time The silvered glass exhibited by E. Varnish & Co. fascinated commentators on the 1851 Great Exhibition. Varnish's salvers, vases, globes and goblets were bold in size and presentation, using non-tarnishing silver, ornamented with coloured casing, cutting and engraving. The process 'added a richness and beauty of colouring to that material of which few could deem it capable of receiving' (Illustrated London News). |

| Bibliographic reference | Chen, xie jun. World Exposition Museum. Shanghai: Shanghai wen yi chu ban she, 2010 ISBN 9787532140503/G.107. 95,97,99,105,pp. ill. |

| Collection | |

| Accession number | CIRC.248-1965 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | December 13, 1997 |

| Record URL |

Download as: JSONIIIF Manifest