Carpet Sample

1950s (made)

| Artist/Maker | |

| Place of origin |

The technique of machine-knotting carpet pile seems to have been developed by Renard Freres in Nonancourt, France. The firm was established in 1880 and apparently began production of machine-knotted carpets almost immediately. Their 'knot-stitch' carpets were produced until World War II, or perhaps a little later. Tompkinsons Ltd. of Kidderminster, England were among several firms to acquire similar looms and they were producing machine-knotted carpets, which they called 'patent knot stitch seamless squares' from about 1921 until the 1950s, by which time production costs had made them uneconomic. While Renard Freres probably concentrated on so-called 'oriental'* designs, Tomkinson included designs by contemporary British artists.

*(NB: since this description was written, the term 'oriental' has fallen from usage and is now considered offensive. The term is repeated here in its historic context where it was used to describe traditional carpets from a wide range of carpet producing countries, from North Africa, through the Middle East to China and Pakistan.)

No machine-knotted carpets were originally sold as hand-knotted, but it was only a matter of time before they began to pass from owner to owner and to be misidentified.

The only way we have found to identify machine-knotting is to look very closely at the direction of the thread in the back of each knot. Like hand-tied knots, each one forms two 'bumps' as it passes around two warp threads. Frequently, but not always, the thread in one 'bump' of a machine-knotted carpet is horizontal and the next 'bump' of the same knot is pulled into a marked diagonal.

*(NB: since this description was written, the term 'oriental' has fallen from usage and is now considered offensive. The term is repeated here in its historic context where it was used to describe traditional carpets from a wide range of carpet producing countries, from North Africa, through the Middle East to China and Pakistan.)

No machine-knotted carpets were originally sold as hand-knotted, but it was only a matter of time before they began to pass from owner to owner and to be misidentified.

The only way we have found to identify machine-knotting is to look very closely at the direction of the thread in the back of each knot. Like hand-tied knots, each one forms two 'bumps' as it passes around two warp threads. Frequently, but not always, the thread in one 'bump' of a machine-knotted carpet is horizontal and the next 'bump' of the same knot is pulled into a marked diagonal.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Cotton with machine-knotted woollen pile |

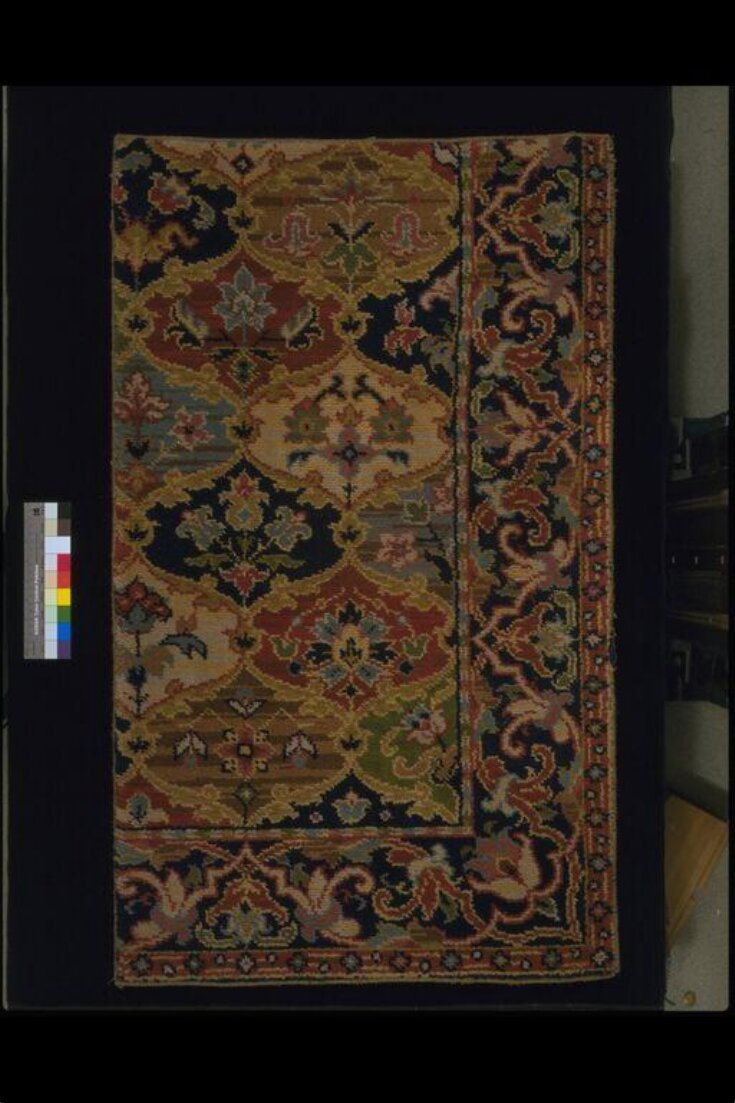

| Brief description | Carpet sample of machine-knotted woollen pile on a cotton warp and weft, probably made in Brno, 1950s |

| Physical description | Carpet sample of machine-knotted woollen pile on a cotton warp and weft. The sample shows part of the border and part of the ground pattern. The ground is divided into ogival compartments each containing a stylised flower or floral spray. There is a very narrow inner border and a slightly wider outer border. The main border is decorated with two meandering stems. Technical details appear to be: Warp: white cotton, 3-ply, 14 threads per inch (50 per dm) Weft: white cotton, 4-ply, 2 parallel threads per shoot, one shoot after each row of knots, 7 knots per inch (28 per dm) Pile: wool, 4-ply, symmetrical knot tied around 2 warp threads; 45 knots per sq. in (700 per sq. dm). Sides and Ends: oversewn with light brown wool. |

| Dimensions |

|

| Credit line | Given by Mr Bill Higbee |

| Subject depicted | |

| Summary | The technique of machine-knotting carpet pile seems to have been developed by Renard Freres in Nonancourt, France. The firm was established in 1880 and apparently began production of machine-knotted carpets almost immediately. Their 'knot-stitch' carpets were produced until World War II, or perhaps a little later. Tompkinsons Ltd. of Kidderminster, England were among several firms to acquire similar looms and they were producing machine-knotted carpets, which they called 'patent knot stitch seamless squares' from about 1921 until the 1950s, by which time production costs had made them uneconomic. While Renard Freres probably concentrated on so-called 'oriental'* designs, Tomkinson included designs by contemporary British artists. *(NB: since this description was written, the term 'oriental' has fallen from usage and is now considered offensive. The term is repeated here in its historic context where it was used to describe traditional carpets from a wide range of carpet producing countries, from North Africa, through the Middle East to China and Pakistan.) No machine-knotted carpets were originally sold as hand-knotted, but it was only a matter of time before they began to pass from owner to owner and to be misidentified. The only way we have found to identify machine-knotting is to look very closely at the direction of the thread in the back of each knot. Like hand-tied knots, each one forms two 'bumps' as it passes around two warp threads. Frequently, but not always, the thread in one 'bump' of a machine-knotted carpet is horizontal and the next 'bump' of the same knot is pulled into a marked diagonal. |

| Collection | |

| Accession number | T.280-1998 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | March 20, 2001 |

| Record URL |

Download as: JSON