Vase

Decorated vase.

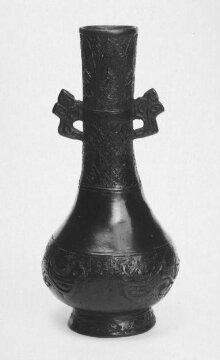

This vase was bought in Paris, and is of the Yuan dynasty (13th to 14th century A.D.). It is similar to other pieces of the same date (R.K). It has two handles, and it has an inset base. The base is soldered-in, and is very yellow in colour. The body decoration is formed in bands. An extra metal patch has been fitted into the base ring, and apparently coloured to match the appearance of the rest of the vase. It is a plain patch in a decorated area, and no attempt has been made to complete the decoration. The base ring shows what appear to be file mark.

Analyses were carried out on the body, the base plate, and the patch, using non-intrusive EDXRF methods. No match for the body metal was found with any of the available standards. The qualitative results showed that the alloy was copper and tin, with a very large amount of lead. The exact composition was not calculated, but the lead figure is in the region of 30% or more. No other manufacturing method except casting would have been possible, using this material. Small amounts of iron and manganese were also detected in the body metal. The base plate metal was completely different, as its colour has suggested. It was a binary alloy of copper and zinc, with a tiny lead content. This is a brass. ‘…brass containing about 20% zinc is particularly suitable for mechanical working such as would be required to hammer sheet out of an ingot (Gordon 1987).’ It seems quite possible that this base could have been made from sheet metal, as its composition has entirely appropriate working properties. Equally, it would have been possible to make it as a casting. The obvious interpretation is that this is a replacement base plate, particularly as it looked quite fresh and yellow. The patch was made from fairly pure copper, containing a small amount of lead. This material would have been very soft, and would have been easy to hammer into place. The repair was almost certainly carried out as a cold process, since the heating and trouble involved with a cast-on patch would have been too extreme for such a small job.

This vase was bought in Paris, and is of the Yuan dynasty (13th to 14th century A.D.). It is similar to other pieces of the same date (R.K). It has two handles, and it has an inset base. The base is soldered-in, and is very yellow in colour. The body decoration is formed in bands. An extra metal patch has been fitted into the base ring, and apparently coloured to match the appearance of the rest of the vase. It is a plain patch in a decorated area, and no attempt has been made to complete the decoration. The base ring shows what appear to be file mark.

Analyses were carried out on the body, the base plate, and the patch, using non-intrusive EDXRF methods. No match for the body metal was found with any of the available standards. The qualitative results showed that the alloy was copper and tin, with a very large amount of lead. The exact composition was not calculated, but the lead figure is in the region of 30% or more. No other manufacturing method except casting would have been possible, using this material. Small amounts of iron and manganese were also detected in the body metal. The base plate metal was completely different, as its colour has suggested. It was a binary alloy of copper and zinc, with a tiny lead content. This is a brass. ‘…brass containing about 20% zinc is particularly suitable for mechanical working such as would be required to hammer sheet out of an ingot (Gordon 1987).’ It seems quite possible that this base could have been made from sheet metal, as its composition has entirely appropriate working properties. Equally, it would have been possible to make it as a casting. The obvious interpretation is that this is a replacement base plate, particularly as it looked quite fresh and yellow. The patch was made from fairly pure copper, containing a small amount of lead. This material would have been very soft, and would have been easy to hammer into place. The repair was almost certainly carried out as a cold process, since the heating and trouble involved with a cast-on patch would have been too extreme for such a small job.

Object details

| Object type | |

| Brief description | Met, China, vess/cont/holders |

| Physical description | Decorated vase. This vase was bought in Paris, and is of the Yuan dynasty (13th to 14th century A.D.). It is similar to other pieces of the same date (R.K). It has two handles, and it has an inset base. The base is soldered-in, and is very yellow in colour. The body decoration is formed in bands. An extra metal patch has been fitted into the base ring, and apparently coloured to match the appearance of the rest of the vase. It is a plain patch in a decorated area, and no attempt has been made to complete the decoration. The base ring shows what appear to be file mark. Analyses were carried out on the body, the base plate, and the patch, using non-intrusive EDXRF methods. No match for the body metal was found with any of the available standards. The qualitative results showed that the alloy was copper and tin, with a very large amount of lead. The exact composition was not calculated, but the lead figure is in the region of 30% or more. No other manufacturing method except casting would have been possible, using this material. Small amounts of iron and manganese were also detected in the body metal. The base plate metal was completely different, as its colour has suggested. It was a binary alloy of copper and zinc, with a tiny lead content. This is a brass. ‘…brass containing about 20% zinc is particularly suitable for mechanical working such as would be required to hammer sheet out of an ingot (Gordon 1987).’ It seems quite possible that this base could have been made from sheet metal, as its composition has entirely appropriate working properties. Equally, it would have been possible to make it as a casting. The obvious interpretation is that this is a replacement base plate, particularly as it looked quite fresh and yellow. The patch was made from fairly pure copper, containing a small amount of lead. This material would have been very soft, and would have been easy to hammer into place. The repair was almost certainly carried out as a cold process, since the heating and trouble involved with a cast-on patch would have been too extreme for such a small job. |

| Dimensions |

|

| Object history | Purchased from Siegfried Bing (Paris), accessioned in 1876. This acquisition information reflects that found in the Asia Department registers, as part of a 2022 provenance research project. |

| Collection | |

| Accession number | 82-1876 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | June 25, 2009 |

| Record URL |

Download as: JSONIIIF Manifest