Dress Fabric

1948 (made)

| Artist/Maker | |

| Place of origin |

Ankara is a printed cotton cloth, produced in a variety of patterns formed by the layering of polychromatic dyes. Fashionable in West and East Africa since the late 19th century, ankara is variously known as 'African wax' or 'Dutch wax' print – despite wax rarely being used in its manufacture. Embodying the overlapping colonial interests that prevailed in the region and beyond, the cloth has a complex history – rooted in trade monopolisation and cultural appropriation, yet acting as a conduit for African agency and resistance.

Originally produced in the Netherlands, ankara emerged from experiments to mechanically replicate batik, an Indonesian wax-print cloth traditionally developed by hand. Early Dutch attempts roller-printed a resin-resist onto both sides of the cloth before dyeing; the resist was then washed out, with additional layers of colour added by repeating this process, hand-blocking and/or roller-printing. The intended export market of Indonesia did not respond well to this imitation batik, as the resin was prone to cracking and bubbling, producing defects in the print. A keen market for the cloth did, however, emerge across West Africa in the 1890s, such that several factories – chiefly in Britain and the Netherlands – began producing ankara with this new customer in mind. Responding to market feedback on popular colours and patterns, European producers adapted ankara designs to suit the tastes of their discerning West African customers. In a collaboration between the consumer, dealer and manufacturer, local sellers would inform European merchants which styles were in demand and suggest motifs that would likely sell well.

By the early 20th century, a cheaper and more refined method of ankara production had been developed, roller-printing only one side of the cloth with a design, without the use of a resin-resist. Many examples of this later ankara purposefully include the imperfections that originally marred Dutch attempts to replicate batik – alluding to the more esteemed resin-resist technique.

Originally produced in the Netherlands, ankara emerged from experiments to mechanically replicate batik, an Indonesian wax-print cloth traditionally developed by hand. Early Dutch attempts roller-printed a resin-resist onto both sides of the cloth before dyeing; the resist was then washed out, with additional layers of colour added by repeating this process, hand-blocking and/or roller-printing. The intended export market of Indonesia did not respond well to this imitation batik, as the resin was prone to cracking and bubbling, producing defects in the print. A keen market for the cloth did, however, emerge across West Africa in the 1890s, such that several factories – chiefly in Britain and the Netherlands – began producing ankara with this new customer in mind. Responding to market feedback on popular colours and patterns, European producers adapted ankara designs to suit the tastes of their discerning West African customers. In a collaboration between the consumer, dealer and manufacturer, local sellers would inform European merchants which styles were in demand and suggest motifs that would likely sell well.

By the early 20th century, a cheaper and more refined method of ankara production had been developed, roller-printing only one side of the cloth with a design, without the use of a resin-resist. Many examples of this later ankara purposefully include the imperfections that originally marred Dutch attempts to replicate batik – alluding to the more esteemed resin-resist technique.

Object details

| Categories | |

| Object type | |

| Materials and techniques | cotton |

| Brief description | Dress fabric, printed cotton, Calico Printers' Association, Great Britain, 1948 |

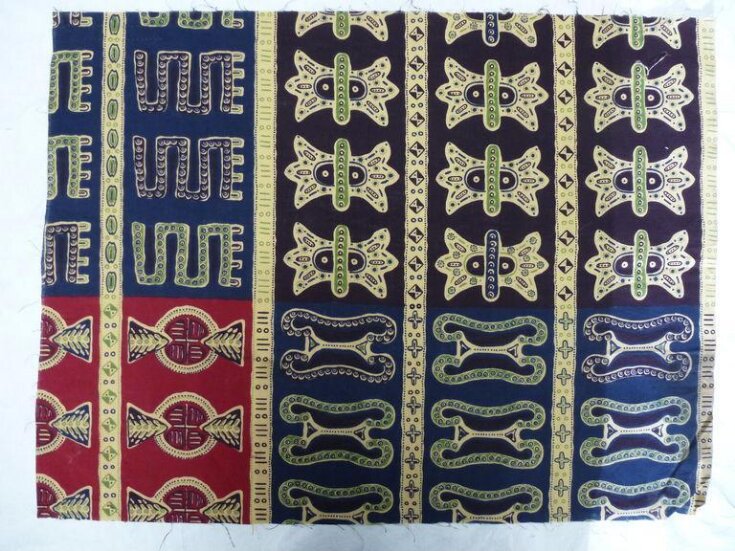

| Physical description | Dress fabric of resist-dyed printed cotton, in shades of red, dark blue, pale yellow and green. The fabric features bands of repeated motifs, based on Adinkra symbols. |

| Object history | Designed for the African market. One of eighteen designs donated by the Calico Printers' Association in 1948. |

| Production | The Calico Printers' Association is one of several companies - principally British or Dutch – who in the early 20th century designed, printed, exported and/or distributed factory-printed cotton textiles for the West African market. The CPA was founded in Manchester in 1899, formed from the merger of 46 textile printing companies and 13 textile merchants. Merchant traders, such as those overseen by the CPA, acted as middlemen between European manufacturers and West African consumers, bridging the geographical and cultural gap that separated them through their use of market knowledge, which ultimately influenced the design and distribution of such textiles. |

| Summary | Ankara is a printed cotton cloth, produced in a variety of patterns formed by the layering of polychromatic dyes. Fashionable in West and East Africa since the late 19th century, ankara is variously known as 'African wax' or 'Dutch wax' print – despite wax rarely being used in its manufacture. Embodying the overlapping colonial interests that prevailed in the region and beyond, the cloth has a complex history – rooted in trade monopolisation and cultural appropriation, yet acting as a conduit for African agency and resistance. Originally produced in the Netherlands, ankara emerged from experiments to mechanically replicate batik, an Indonesian wax-print cloth traditionally developed by hand. Early Dutch attempts roller-printed a resin-resist onto both sides of the cloth before dyeing; the resist was then washed out, with additional layers of colour added by repeating this process, hand-blocking and/or roller-printing. The intended export market of Indonesia did not respond well to this imitation batik, as the resin was prone to cracking and bubbling, producing defects in the print. A keen market for the cloth did, however, emerge across West Africa in the 1890s, such that several factories – chiefly in Britain and the Netherlands – began producing ankara with this new customer in mind. Responding to market feedback on popular colours and patterns, European producers adapted ankara designs to suit the tastes of their discerning West African customers. In a collaboration between the consumer, dealer and manufacturer, local sellers would inform European merchants which styles were in demand and suggest motifs that would likely sell well. By the early 20th century, a cheaper and more refined method of ankara production had been developed, roller-printing only one side of the cloth with a design, without the use of a resin-resist. Many examples of this later ankara purposefully include the imperfections that originally marred Dutch attempts to replicate batik – alluding to the more esteemed resin-resist technique. |

| Collection | |

| Accession number | CIRC.409B-1948 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | June 24, 2009 |

| Record URL |

Download as: JSON