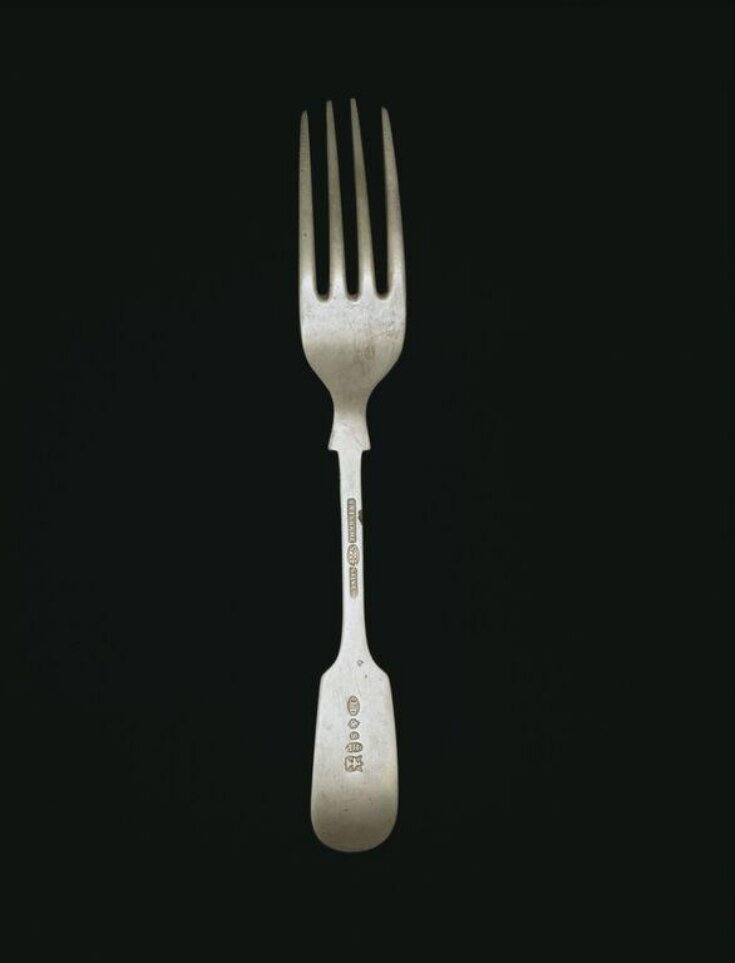

Brisbane Silver

Fork

ca. 1890 (made)

ca. 1890 (made)

| Artist/Maker | |

| Place of origin |

“ The substitution of electro-plate for real silver is now so common in households where the latter would be regarded as a superfluous luxury, that the sternest advocate of true principles in art-manufacture would scarcely require an apology for its use.” (Charles Eastlake, Hints on Household Taste, 1878)

George Richard Elkington and his cousin and partner, Henry Elkington successfully developed electroplating, electrotyping and electrogilding processes from earlier experiments and made them commercially viable. The cousins were not inventors but innovators who, by applying the techniques to industry, revolutionized the silver and plating trades all over the world. In the 1840s, licences to make the new products were sold widely in Britain and abroad to firms such as Christofle & Co. in Paris. Electroplate, a cheaper and more durable substitute for silver, replaced Sheffield plate within ten years and challenged the supremacy of silver on the dining tables and in the drawing rooms of Europe.

The power of the machinery and new technology now at the disposal of the silver industry could produce thousands of identical items to a standard formula of design, quality and price. The focus of silver and silver product manufacture moved from London to the new factories of Birmingham and Sheffield.

George Richard Elkington and his cousin and partner, Henry Elkington successfully developed electroplating, electrotyping and electrogilding processes from earlier experiments and made them commercially viable. The cousins were not inventors but innovators who, by applying the techniques to industry, revolutionized the silver and plating trades all over the world. In the 1840s, licences to make the new products were sold widely in Britain and abroad to firms such as Christofle & Co. in Paris. Electroplate, a cheaper and more durable substitute for silver, replaced Sheffield plate within ten years and challenged the supremacy of silver on the dining tables and in the drawing rooms of Europe.

The power of the machinery and new technology now at the disposal of the silver industry could produce thousands of identical items to a standard formula of design, quality and price. The focus of silver and silver product manufacture moved from London to the new factories of Birmingham and Sheffield.

Object details

| Categories | |

| Object type | |

| Title | Brisbane Silver (manufacturer's title) |

| Materials and techniques | Nickel silver |

| Brief description | Fork, electroplated nickel silver fork, trade name 'Brisbane Silver' made by James Deakin & Sons Ltd., Sheffield, ca. 1890 |

| Physical description | Fiddle thread pattern (with hard shoulders) |

| Dimensions |

|

| Production type | Mass produced |

| Marks and inscriptions | "BRISBANE" within a rectangular lozenge with chamfered corners, "S, a pair of crossed arrows, F" within an oval shield, "SILVER" within a rectangular shield with chamfered corners,"JD" within an oval shiles, "&" within an hexagonal shield, "S" within a circular shield, "BP" within an oval shield (at right angles to the main string), and a device within an heraldic shield. Note Along the centre of the back of the stem Marked on the shaft with the trade name Brisbane SILVER separated by a crossed arrows, and on the handle with the maker’s marks of James Deakin and Son of Sheffield |

| Gallery label |

|

| Credit line | Given by Mrs Ena Eatwell |

| Object history | Gift - Ena Eatwell |

| Production | Reason For Production: Retail |

| Summary | “ The substitution of electro-plate for real silver is now so common in households where the latter would be regarded as a superfluous luxury, that the sternest advocate of true principles in art-manufacture would scarcely require an apology for its use.” (Charles Eastlake, Hints on Household Taste, 1878) George Richard Elkington and his cousin and partner, Henry Elkington successfully developed electroplating, electrotyping and electrogilding processes from earlier experiments and made them commercially viable. The cousins were not inventors but innovators who, by applying the techniques to industry, revolutionized the silver and plating trades all over the world. In the 1840s, licences to make the new products were sold widely in Britain and abroad to firms such as Christofle & Co. in Paris. Electroplate, a cheaper and more durable substitute for silver, replaced Sheffield plate within ten years and challenged the supremacy of silver on the dining tables and in the drawing rooms of Europe. The power of the machinery and new technology now at the disposal of the silver industry could produce thousands of identical items to a standard formula of design, quality and price. The focus of silver and silver product manufacture moved from London to the new factories of Birmingham and Sheffield. |

| Bibliographic reference | John Culme The Directory of Gold & Silversmiths, Jewellers and Allied Traders 1838-1914, From the London Assay Office Registers, Vol.1, Woodbridge, Antique Collectors' Club, 1987, pp114-15 ISBN 1851490698 |

| Collection | |

| Accession number | M.10-1999 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | February 16, 2000 |

| Record URL |

Download as: JSON