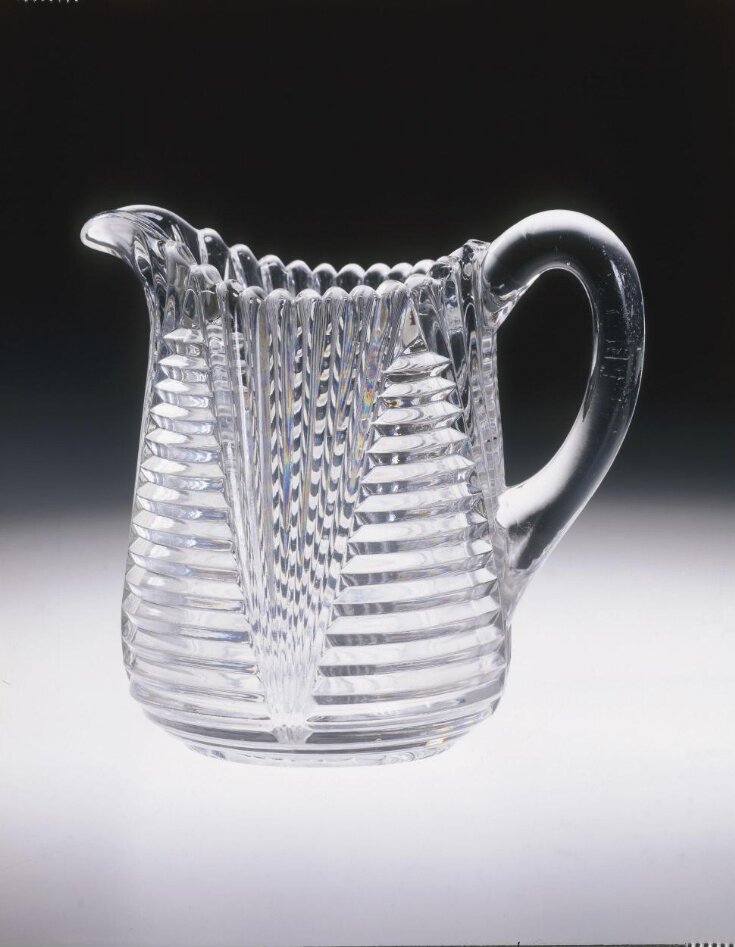

Jug

1891 (design registered)

| Artist/Maker | |

| Place of origin |

Object Type

This jug is entirely functional and made for daily use. Extensive glass table services became increasingly popular towards the end of the 19th century. Cheaply made, in pressed glass, such sets were often elaborate and became widely available.

Materials & Making

The technique of press-moulding glass with the aid of a hand-operated machine was first perfected in the United States of America in the early 1820s. It took only two people to shape a measured quantity of hot glass in a heated metal mould. By simply depressing a lever, a metal plunger was lowered into the glass, forcing it into the patterned mould. By the 1830s this method had spread to Europe and Britain, giving rise to stylistic changes and revolutionising the availability of glassware. The technique made the mid- to late 19th century the first period of true mass production. In the 1890s the introduction of steam-powered presses improved quality while cutting costs even further.

This jug is entirely functional and made for daily use. Extensive glass table services became increasingly popular towards the end of the 19th century. Cheaply made, in pressed glass, such sets were often elaborate and became widely available.

Materials & Making

The technique of press-moulding glass with the aid of a hand-operated machine was first perfected in the United States of America in the early 1820s. It took only two people to shape a measured quantity of hot glass in a heated metal mould. By simply depressing a lever, a metal plunger was lowered into the glass, forcing it into the patterned mould. By the 1830s this method had spread to Europe and Britain, giving rise to stylistic changes and revolutionising the availability of glassware. The technique made the mid- to late 19th century the first period of true mass production. In the 1890s the introduction of steam-powered presses improved quality while cutting costs even further.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Press-moulded glass |

| Brief description | Jug, England (Manchester), made by Percival, Vickers & Co. Ltd., 1891-1900, C.137-1983 . |

| Dimensions |

|

| Style | |

| Marks and inscriptions | Registration number for 13/3/1891 (Registration number) |

| Credit line | Gift of M. J Franklin |

| Object history | Made by Percival, Vickers & Co. Ltd. (1891-1900) Made in Manchester |

| Summary | Object Type This jug is entirely functional and made for daily use. Extensive glass table services became increasingly popular towards the end of the 19th century. Cheaply made, in pressed glass, such sets were often elaborate and became widely available. Materials & Making The technique of press-moulding glass with the aid of a hand-operated machine was first perfected in the United States of America in the early 1820s. It took only two people to shape a measured quantity of hot glass in a heated metal mould. By simply depressing a lever, a metal plunger was lowered into the glass, forcing it into the patterned mould. By the 1830s this method had spread to Europe and Britain, giving rise to stylistic changes and revolutionising the availability of glassware. The technique made the mid- to late 19th century the first period of true mass production. In the 1890s the introduction of steam-powered presses improved quality while cutting costs even further. |

| Other number | 0903 - Glass gallery number |

| Collection | |

| Accession number | C.137-1983 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | December 13, 1997 |

| Record URL |

Download as: JSONIIIF Manifest