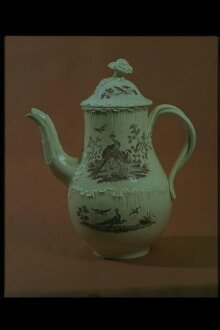

Coffee Pot and Cover

ca. 1775 (made)

| Artist/Maker | |

| Place of origin |

Wedgwood's elegant service illustrates two of the key contributions that eighteenth-century Britain made to ceramic history: creamware, a type of white earthenware, and transfer-printing, an invention that revolutionized ceramic production worldwide.

As a material, creamware had several advantages over porcelain and its other rivals. It was cheap to make; it was strengthened with calcined flint, which made it durable and encouraged thin potting; and the colour and smooth glaze made it hygienic and suitable for eating and drinking. Developed in Staffordshire during the 1740s and 1750s, creamware was perfected by Josiah Wedgwood in the 1760s. It proved enormously popular, remaining in production until the 1820s, and was exported throughout the world.

Creamware was attractive when left plain, but it provided an excellent background for restrained enamel painting or for on-glaze transfer-printing of the type shown here. Transfer-printing over the glaze involved printing a design onto a layer of gelatin (animal glue), which was then applied to the body of the ware, thus transferring the design. The revolutionary importance of the technique was that it enabled manufacturers to achieve high-quality decoration at a relatively low cost, for although engravers put much work into the printing plates, the actual decoration of the wares could be carried out by less skilled hands.

As a material, creamware had several advantages over porcelain and its other rivals. It was cheap to make; it was strengthened with calcined flint, which made it durable and encouraged thin potting; and the colour and smooth glaze made it hygienic and suitable for eating and drinking. Developed in Staffordshire during the 1740s and 1750s, creamware was perfected by Josiah Wedgwood in the 1760s. It proved enormously popular, remaining in production until the 1820s, and was exported throughout the world.

Creamware was attractive when left plain, but it provided an excellent background for restrained enamel painting or for on-glaze transfer-printing of the type shown here. Transfer-printing over the glaze involved printing a design onto a layer of gelatin (animal glue), which was then applied to the body of the ware, thus transferring the design. The revolutionary importance of the technique was that it enabled manufacturers to achieve high-quality decoration at a relatively low cost, for although engravers put much work into the printing plates, the actual decoration of the wares could be carried out by less skilled hands.

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 2 parts.

|

| Materials and techniques | Creamware, transfer-printed in purple enamel |

| Brief description | Coffee pot and cover, creamware, transfer-printed in purple enamel, made at Josiah Wedgwood and Sons Ltd., Etruria, printed by Guy Green in Liverpool, ca. 1775. |

| Physical description | Coffee pot and cover of earthenware transfer-printed with purple enamel over the glaze and moulded. |

| Dimensions |

|

| Credit line | Given by Lady Charlotte Schreiber |

| Subjects depicted | |

| Summary | Wedgwood's elegant service illustrates two of the key contributions that eighteenth-century Britain made to ceramic history: creamware, a type of white earthenware, and transfer-printing, an invention that revolutionized ceramic production worldwide. As a material, creamware had several advantages over porcelain and its other rivals. It was cheap to make; it was strengthened with calcined flint, which made it durable and encouraged thin potting; and the colour and smooth glaze made it hygienic and suitable for eating and drinking. Developed in Staffordshire during the 1740s and 1750s, creamware was perfected by Josiah Wedgwood in the 1760s. It proved enormously popular, remaining in production until the 1820s, and was exported throughout the world. Creamware was attractive when left plain, but it provided an excellent background for restrained enamel painting or for on-glaze transfer-printing of the type shown here. Transfer-printing over the glaze involved printing a design onto a layer of gelatin (animal glue), which was then applied to the body of the ware, thus transferring the design. The revolutionary importance of the technique was that it enabled manufacturers to achieve high-quality decoration at a relatively low cost, for although engravers put much work into the printing plates, the actual decoration of the wares could be carried out by less skilled hands. |

| Other number | Sch. II 406&A - Schreiber number |

| Collection | |

| Accession number | 414:1155/&A-1885 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | May 5, 2009 |

| Record URL |

Download as: JSONIIIF Manifest