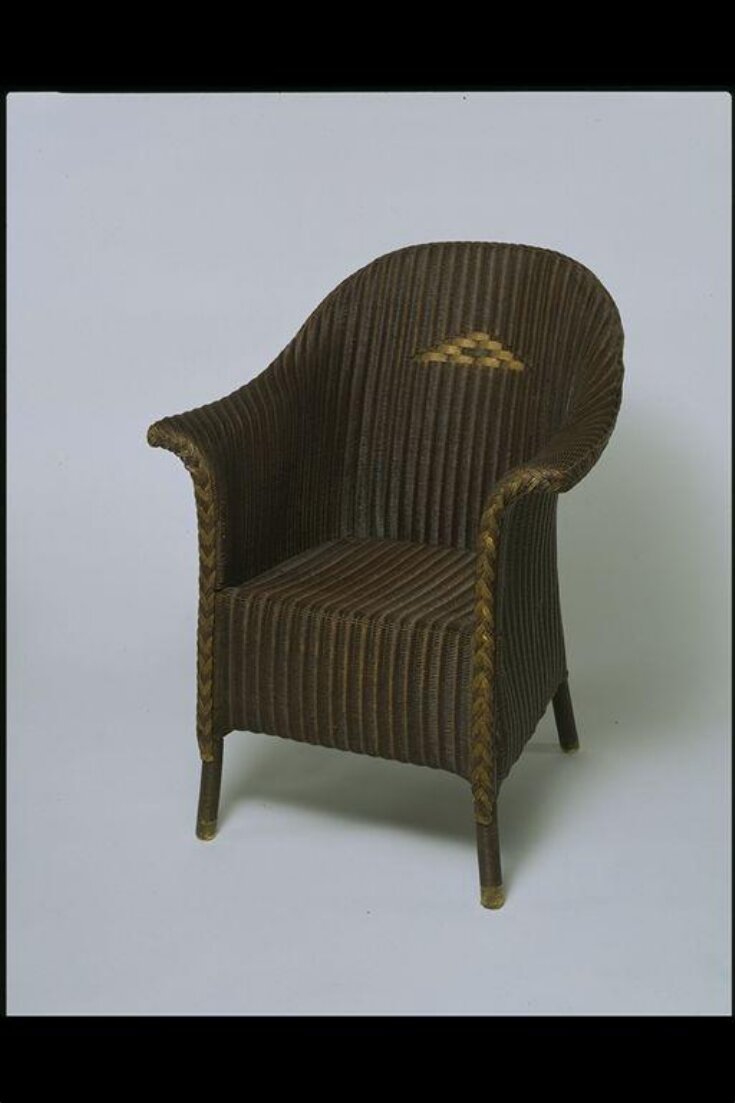

Model 464

Armchair

11/1930 (made)

11/1930 (made)

| Artist/Maker | |

| Place of origin |

In 1921 Lusty, a packing case manufacturer, acquired the rights to mass-produce furniture using the American method of weaving twisted paper fibre, patented under the name Lloyd Loom. The product, which could be woven in a variety of patterns, was attached over bentwood frames and often imitated popular furniture forms made in other materials.

Lloyd Loom furniture replaced wicker furniture, which was more expensive and less durable. It was produced in vast quantities from the 1930s to the 1960s. Production-line methods reduced costs but allowed little creative input for individual craftsmen. This chair is given a Moderne feel by the step pattern and the black and gold colouring.

Lloyd Loom furniture replaced wicker furniture, which was more expensive and less durable. It was produced in vast quantities from the 1930s to the 1960s. Production-line methods reduced costs but allowed little creative input for individual craftsmen. This chair is given a Moderne feel by the step pattern and the black and gold colouring.

Object details

| Categories | |

| Object type | |

| Title | Model 464 (manufacturer's title) |

| Materials and techniques | Lloyd Loom woven fibre over steam-bent beech frame |

| Brief description | Armchair, manufactured by W. Lusty and Sons, London, date stamped November 1930 |

| Physical description | Armchair with solid back and arms, in black Lloyd Loom fibre with gold toning, a 'step' pattern decorates the back. It is finished in Jacobean stain and the gold detail was applied by hand. |

| Dimensions |

|

| Marks and inscriptions |

|

| Gallery label |

|

| Historical context | In 1921 Lusty, a packing case manufacturer, acquired the rights to mass-produce furniture using the American method of weaving twisted paper fibre patented under the name Lloyd Loom. The product, which could be woven in a variety of patterns, was attached over bentwood frames and often imitated popular furniture forms made in other materials. Replacing wicker furniture which was more expensive and less durable, Lloyd Loom furniture was produced in vast quantities from the 1930s and the 1960s. Production-line methods reduced costs but allowed little creative input for individual craftsmen. This chair is given a Moderne feel by the step pattern in the black and gold toning. [Gareth Williams, 'British Design at Home', p.110] |

| Summary | In 1921 Lusty, a packing case manufacturer, acquired the rights to mass-produce furniture using the American method of weaving twisted paper fibre, patented under the name Lloyd Loom. The product, which could be woven in a variety of patterns, was attached over bentwood frames and often imitated popular furniture forms made in other materials. Lloyd Loom furniture replaced wicker furniture, which was more expensive and less durable. It was produced in vast quantities from the 1930s to the 1960s. Production-line methods reduced costs but allowed little creative input for individual craftsmen. This chair is given a Moderne feel by the step pattern and the black and gold colouring. |

| Bibliographic references |

|

| Collection | |

| Accession number | W.6-1992 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | February 8, 2000 |

| Record URL |

Download as: JSON