111 Navy Chair

Chair

2022 (made)

2022 (made)

| Artist/Maker | |

| Place of origin |

The 111 The Navy chair is the first mass produced plastic chair to make use of recycled PET bottles, it launched in 2010. The original 1006 Navy chair was made by Emeco in 1944 for the US Navy. It was built by hand from aluminium, which made it both light to lift and non-corrosive. The 111 Navy chair has the same form as the 1006 Navy but is made from as many as 111 recycled PET bottles. The project is a collaboration between the drinks company Coca Cola and Emeco.

Recycled PET is often recycled into soft plastic materials such as fabrics. Therefore, the challenge for Emeco was to create a plastic material that was sturdy enough to be used in furniture production. The plastic material used for the chair is created from recycled PET plastic that is made into pellets, an estimated six kilos of recycled PET pellets are needed for each chair. The pellets are then mixed with a glass fibre compound, to add stability, and a colour pigment to make the colour uniform. It is estimated that 65% of the material composition is made up of recycled PET and 35% of glass fibre. The molten plastic is then injection moulded into the form of the chair. After moulding, an H-shaped brace is attached to the legs to make them sturdier. Even though the injection-moulding process is entirely machine-based, the addition of the H-shaped brace, means there is also a level of hand finish to the chair.

The idea of turning bottles into chairs is to keep plastic bottles out of the global waste stream for longer, by creating a long-lasting circular economy product. The V&A holds other designs made from post-consumer waste in its collection, for example the RCP2 chair by Jane Atfield from 1992, which is made from boards created from chipped plastic consumer waste (W.4-1996) and a chair by Bär & Knell that uses molten plastic packaging to shape a chair from 1996 (W.12-1996). Both examples are small-scale productions, while the 111 Navy Chair represents this same tendency for recycling within furniture production but at a greater scale.

Recycled PET is often recycled into soft plastic materials such as fabrics. Therefore, the challenge for Emeco was to create a plastic material that was sturdy enough to be used in furniture production. The plastic material used for the chair is created from recycled PET plastic that is made into pellets, an estimated six kilos of recycled PET pellets are needed for each chair. The pellets are then mixed with a glass fibre compound, to add stability, and a colour pigment to make the colour uniform. It is estimated that 65% of the material composition is made up of recycled PET and 35% of glass fibre. The molten plastic is then injection moulded into the form of the chair. After moulding, an H-shaped brace is attached to the legs to make them sturdier. Even though the injection-moulding process is entirely machine-based, the addition of the H-shaped brace, means there is also a level of hand finish to the chair.

The idea of turning bottles into chairs is to keep plastic bottles out of the global waste stream for longer, by creating a long-lasting circular economy product. The V&A holds other designs made from post-consumer waste in its collection, for example the RCP2 chair by Jane Atfield from 1992, which is made from boards created from chipped plastic consumer waste (W.4-1996) and a chair by Bär & Knell that uses molten plastic packaging to shape a chair from 1996 (W.12-1996). Both examples are small-scale productions, while the 111 Navy Chair represents this same tendency for recycling within furniture production but at a greater scale.

Object details

| Categories | |

| Object type | |

| Titles |

|

| Materials and techniques | Each chair is produced from at around 111 plastic bottles. Made from 65% recycled PET (plastic bottles), pigment and 35% fibreglass for reinforcement. Carbon footprint: 20.76 kg CO2e |

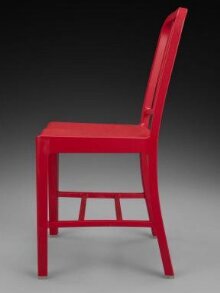

| Brief description | Red 111 Navy Chair designed by Emeco, recycled PET bottles, 2010, collaboration with Coca-Cola |

| Physical description | A red plastic chair with a backrest |

| Dimensions |

|

| Credit line | Given by Emeco |

| Association | |

| Summary | The 111 The Navy chair is the first mass produced plastic chair to make use of recycled PET bottles, it launched in 2010. The original 1006 Navy chair was made by Emeco in 1944 for the US Navy. It was built by hand from aluminium, which made it both light to lift and non-corrosive. The 111 Navy chair has the same form as the 1006 Navy but is made from as many as 111 recycled PET bottles. The project is a collaboration between the drinks company Coca Cola and Emeco. Recycled PET is often recycled into soft plastic materials such as fabrics. Therefore, the challenge for Emeco was to create a plastic material that was sturdy enough to be used in furniture production. The plastic material used for the chair is created from recycled PET plastic that is made into pellets, an estimated six kilos of recycled PET pellets are needed for each chair. The pellets are then mixed with a glass fibre compound, to add stability, and a colour pigment to make the colour uniform. It is estimated that 65% of the material composition is made up of recycled PET and 35% of glass fibre. The molten plastic is then injection moulded into the form of the chair. After moulding, an H-shaped brace is attached to the legs to make them sturdier. Even though the injection-moulding process is entirely machine-based, the addition of the H-shaped brace, means there is also a level of hand finish to the chair. The idea of turning bottles into chairs is to keep plastic bottles out of the global waste stream for longer, by creating a long-lasting circular economy product. The V&A holds other designs made from post-consumer waste in its collection, for example the RCP2 chair by Jane Atfield from 1992, which is made from boards created from chipped plastic consumer waste (W.4-1996) and a chair by Bär & Knell that uses molten plastic packaging to shape a chair from 1996 (W.12-1996). Both examples are small-scale productions, while the 111 Navy Chair represents this same tendency for recycling within furniture production but at a greater scale. |

| Collection | |

| Accession number | W.13-2023 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | March 8, 2023 |

| Record URL |

Download as: JSON