Instructions

ca. 1955 (made)

| Artist/Maker | |

| Place of origin |

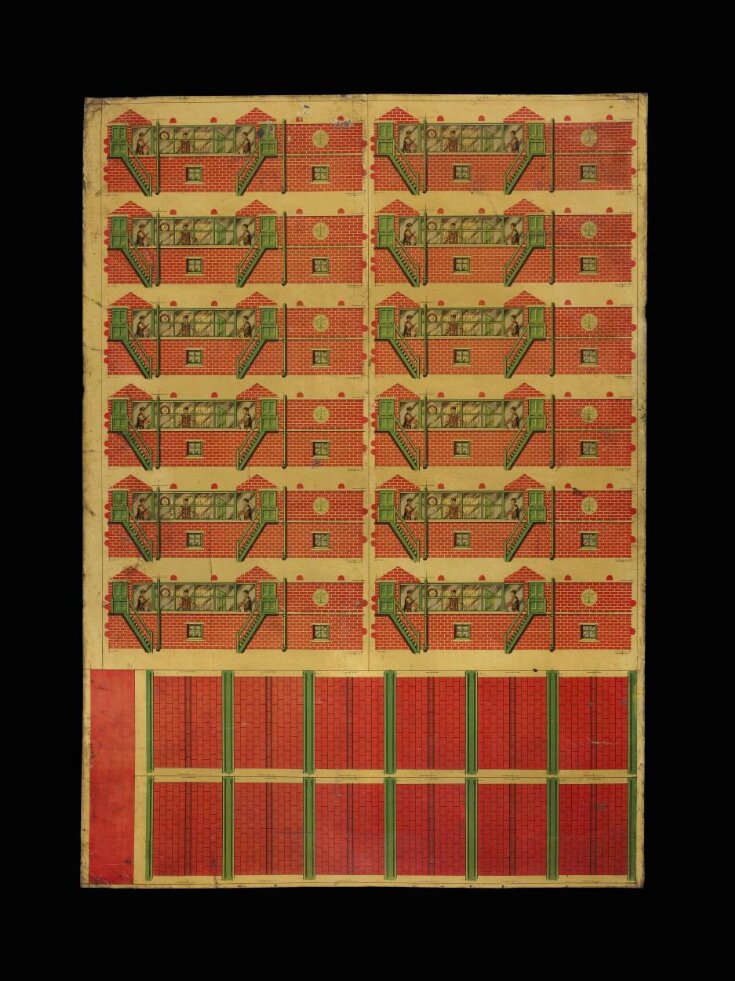

Rectangular tinplate sheet printed with a repeating design of a railway signals box. There are 12 buildings in total, each being a net to form a tinplate toy. At the bottom are separate nets to form the buildings' roofs. The designs are printed in brick red, with green detailing for window frames, with a scene inside of a railway signalman stood behind the window in front of a timetable and clock.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Colour lithographed tin-plated mild steel |

| Brief description | Guide sheet for unformed railway signal box toy, Self-Opening Tin Box Company for Wells-Brimtoy, Barking, Essex, 1950s |

| Physical description | Rectangular tinplate sheet printed with a repeating design of a railway signals box. There are 12 buildings in total, each being a net to form a tinplate toy. At the bottom are separate nets to form the buildings' roofs. The designs are printed in brick red, with green detailing for window frames, with a scene inside of a railway signalman stood behind the window in front of a timetable and clock. |

| Dimensions |

|

| Marks and inscriptions | 'BRIMTOY BRAND / BRITISH MADE' Note Printed inside a roundel on each building's right-hand wall. |

| Credit line | Given by Stephen Enever |

| Object history | This printers' guide sheet was used at the Self-Opening Tin Box Company's factory in Barking, Essex to make tinplate sheets which were sent to Wells-Brimtoy's factory in Walthamstow to be made into toys. The donor obtained both sheets (B.53 and 54-2022) directly from their place of making in 1980, by which time the Self-Opening Tin Box Company's factory (then known as Nacanco Plant 3) print shop was closing. At the time, the donor was manager of the factory's print department. |

| Historical context | Toy manufacturing tends to closely follow social and technological developments. Tinplate is a sheet of mild steel plated with tin. Tinplate toys are, generally speaking, made from one or several sheets of tinplate, pressed and bent into shape and fastened with integral tabs. The first tinplate toys resulted from the introduction of metal stamping machines in 1815, which allowed for mass production of cheap, light and durable metal toys. The introduction of offset lithography into the process from the late-1880s, to print as opposed to painting designs onto the tinplate, further sped up and economised the manufacturing process. Tinplate toys enjoyed several periods of popularity during the 20th century. The easy availability of raw materials allowed production to first begin in the United States. However, at the beginning of the century, German companies such as Lehmann dominated the market. Anti-German sentiments meant that American companies gained ground during and after the First World War, with the world’s largest and most successful firm from the 1920s-1960s being New York-based Louis Marx and Company. Most tinplate production was suspended during the Second World War, with those resources redirected to the war effort. After the war, toymaking formed a part of industrial recovery in the defeated Axis powers, with Japan in particular developing a strong reputation for tinplate. This was due in part to wartime developments in printing processes, allowing for better detail, and also because of the excellence of Japanese engineers in miniaturising motors and components, imbibing toys with a wide range of potential movements. In Britain, toy production similarly boomed during the 20th century, broadly until the 1960s when many European and North American manufacturers found themselves faced with rising costs and competition from Far Eastern industrial centres, such as Hong Kong and China. In terms of tinplate, Walthamstow-based Wells and Wales-based Mettoy led the field in the UK. Wells was founded in 1919 by Alfred Wells, who aimed to take advantage of the loss of German companies’ dominance. In 1932, they merged with Brimtoy (British Metal and Toy Manufacturers) – another manufacturer of cheap tinplate toys – who had been caught out by the economic strains of the Great Depression. The newly merged company moved to a new factory in Walthamstow the same year. The company traded until about 1965 using a number of trademarks – Wells, Wells-Brimtoy, Brimtoy, Weslotoys, A.J. Wells, Pocketoy – which make their products notoriously hard to identify and date, especially as they regularly left their marks off of their cheaper models. The Self-Opening Tin Box Company, Ltd. was founded by George Featherstone Griffin (1825-1902), who had turned to manufacture of metal containers following his success with designing an all-metal railway track. His 1880 patent for a type of metal box or can that could be opened without use of tools was the basis for the formation of the company. Originally based in central London, the factory moved to Barking, Essex in 1910. The company made a variety of items, including confectionary tins, ammunition boxes and toys. They were purchased in 1967 by the National Can Corporation of America (aka Nacanco Ltd.), and by 1980 they were the second largest manufacturer of cans in the UK. |

| Production | This object is a working pass sheet for creating tinplate toys. As they were made and used several decades before the pantone ink system, the colours for the designs on this type of toy were mixed and matched using the printer's own skill and judgement. |

| Subjects depicted | |

| Collection | |

| Accession number | B.54-2022 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | October 28, 2021 |

| Record URL |

Download as: JSONIIIF Manifest