3D Printed Door Handle

2021

| Artist/Maker | |

| Place of origin |

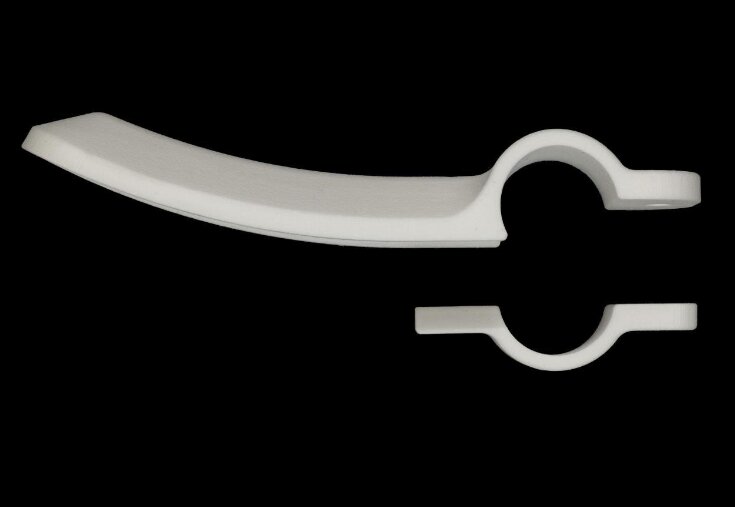

These are a set of 3D-printed door handle openers from Materialise, created to enable users to open doors without touching them with their hands. They are a design response to a new need at the time of the COVID-19 pandemic when surfaces were understood to be sites widespread transmission of the virus.

Materialise was founded in 1990 in Leuven in Belgium by design couple Hilde Ingelaere and Wilfried Vancraen to rapid prototype. This is a process where designers quickly fabricate a design a scale model of a physical part or assembly using three-dimensional computer aided design through 3D printing. Ingelaere and Vancraen went on to create 3D-printing software, platforms and services for industries such as healthcare – including producing anatomical models for doctors using CT (computed tomography) image data and models for full face transplants – automotive and aerospace, art and design, and consumer goods. They also created one of the first online ordering services ‘Materialise OnSite’ in 1997 to allow users to print designs, even if they did not have a high specification printer themselves. Later, in 2009, Materialise created i.materialise, where users could upload, sell, print and share their own designs with others.

Materialise’s 3D-printed door handle openers were in extensive use during the pandemic in hospitals, care homes and in hospitality with the aim to prevent contamination through touching. Attached to door handles with screws, users could open a door handle by pulling or pushing with an elbow or arm, rather than a hand, avoiding contact with a surface that may have been previously contaminated by another person who may have come into contact with COVID-19.

The 3D-printed door handle openers are fabricated using laser-sintering (which allows for mass production) or in multi-jet fusion (which allows precision and accuracy) in Nylon PA12, created from a fine polyamide powder. This material is often used because of its low cost and high precision, it also has chemical resistance and limited moisture absorption, making it ideal for a project such as this in which the ability to clean the door handles effectively is important. PA12 is also commonly used in bioengineering, such as in the application of implants. The openers are fitted to existing doorhandles and, Materialise explain that the openers themselves are dishwasher safe once screws have been removed.

The door handle openers were first conceived during a company ‘sprint’ – a term originating from ‘agile’ software development in which a product is created, iterated, tested and produced in a short set period of time – to improve the working conditions in Materialise’s workshops and offices. This effort was partly in response to a study published on 17 March 2020 in the New England Journal of Medicine which confirmed that coronavirus remains active on surfaces such as plastic and stainless steel for up to 72 hours.

The first design was made without screws and clipped together, and although it seemed ergonomically optimised, it would have been expensive to print due to the specific material needed to support the weight, the volume of the material needed, and required use of more expensive 3D printers that would have prohibited access to many that needed the handles. Due to these challenges, this design did not make it to the final stages of production. Instead, the team took lessons from the initial sprint session and focused on a design that didn’t need as much support structure in the printing process (extra structure produced during printing to support the item being produced as it is produced), and therefore were less wasteful. In all it took the Materialise team 24 hours to create, test and validate the door handle before they were able to upload the open-source designs to be downloaded for free on their platforms. The designs were also available online to purchase as a set of two ready-printed openers from the company website, accompanied with a sticker bearing the slogan “Do No Harm, Use Your Arm!”.

Following the initial sprint, the Materialise team then expanded on the first design to create a set of openers that would fit on a number of common door handles, such as lever (Cylindrical, Narrow, Cylindrical, Wide) and bar doors (Rectangular, Wide, Rectangular, Narrow). Ensuring that the door handle could be used by as many people as possible , each door handle is affixed with M4 countersunk screws (ISO 10642), a common household screw. Feedback was received from early users which helped to improve the design, for example, if the handle was rotating too far in use, the design could be adjusted, or if the handle snapped, revealing a stress point, the instructions for the direction of printing could be changed. Further door handles were subsequently created as relationships with users developed, for example, a door handle for vertical hydraulic bars was requested by bakeries.

The team created a specific design for spherical knob handles (Spherical, Moving, Large), most commonly used in North America, and although it is the only door handle opener not for sale online as it is more expensive to hold as inventory due to the volume of the plastic and technical complexity involved in printing. The .STL files are free to download for users to print themselves with guidance on the strongest materials to use. This design for spherical knob handles was one of the more challenging for the team, due to the challenge of gaining the right traction to turn a spherical handle.

The 3D-printed door handle openers join the collection as an example of rapid prototyping at a time of crisis, when designers and engineers use additive manufacturing to quickly tackle complex problems surrounding barriers to health and wellbeing in the built and medical environment. They join the museum’s growing collection of 3D-printed design, including the Gynepunk 3D-printed speculum (CD.20-2020), the 3D-printed gun ‘The Liberator’ (CD.40-2014), ‘Radical Love’ by Heather Dewey Hagborg (CD.28-2018) and the ECAL Digital Market (CD.22-62-2020, furthering our understanding of additive manufacturing in contemporary design practice today.

These door handle openers also serve to highlight the inaccessibility of current interior and industrial design, as their function enables access to other users, such as disabled people that might need to adapt doors to better work for them. This demonstrates where a design not originally intended for disabled users can be appropriated for the needs of those that might benefit from the adaptations it can provide. An accompanying object in the collection, although designed initially specifically for disabled users, is the Yard-arm pick-up stick by DA Morton (CIRC.19-1966). This pick-up stick highlights the inadequacies of the built and domestic environment for disabled people, while also going on to become popular in wider use for non-disabled individuals, for example in its use in hygiene environments where the ability to distance oneself from potentially harmful material is important.

Materialise was founded in 1990 in Leuven in Belgium by design couple Hilde Ingelaere and Wilfried Vancraen to rapid prototype. This is a process where designers quickly fabricate a design a scale model of a physical part or assembly using three-dimensional computer aided design through 3D printing. Ingelaere and Vancraen went on to create 3D-printing software, platforms and services for industries such as healthcare – including producing anatomical models for doctors using CT (computed tomography) image data and models for full face transplants – automotive and aerospace, art and design, and consumer goods. They also created one of the first online ordering services ‘Materialise OnSite’ in 1997 to allow users to print designs, even if they did not have a high specification printer themselves. Later, in 2009, Materialise created i.materialise, where users could upload, sell, print and share their own designs with others.

Materialise’s 3D-printed door handle openers were in extensive use during the pandemic in hospitals, care homes and in hospitality with the aim to prevent contamination through touching. Attached to door handles with screws, users could open a door handle by pulling or pushing with an elbow or arm, rather than a hand, avoiding contact with a surface that may have been previously contaminated by another person who may have come into contact with COVID-19.

The 3D-printed door handle openers are fabricated using laser-sintering (which allows for mass production) or in multi-jet fusion (which allows precision and accuracy) in Nylon PA12, created from a fine polyamide powder. This material is often used because of its low cost and high precision, it also has chemical resistance and limited moisture absorption, making it ideal for a project such as this in which the ability to clean the door handles effectively is important. PA12 is also commonly used in bioengineering, such as in the application of implants. The openers are fitted to existing doorhandles and, Materialise explain that the openers themselves are dishwasher safe once screws have been removed.

The door handle openers were first conceived during a company ‘sprint’ – a term originating from ‘agile’ software development in which a product is created, iterated, tested and produced in a short set period of time – to improve the working conditions in Materialise’s workshops and offices. This effort was partly in response to a study published on 17 March 2020 in the New England Journal of Medicine which confirmed that coronavirus remains active on surfaces such as plastic and stainless steel for up to 72 hours.

The first design was made without screws and clipped together, and although it seemed ergonomically optimised, it would have been expensive to print due to the specific material needed to support the weight, the volume of the material needed, and required use of more expensive 3D printers that would have prohibited access to many that needed the handles. Due to these challenges, this design did not make it to the final stages of production. Instead, the team took lessons from the initial sprint session and focused on a design that didn’t need as much support structure in the printing process (extra structure produced during printing to support the item being produced as it is produced), and therefore were less wasteful. In all it took the Materialise team 24 hours to create, test and validate the door handle before they were able to upload the open-source designs to be downloaded for free on their platforms. The designs were also available online to purchase as a set of two ready-printed openers from the company website, accompanied with a sticker bearing the slogan “Do No Harm, Use Your Arm!”.

Following the initial sprint, the Materialise team then expanded on the first design to create a set of openers that would fit on a number of common door handles, such as lever (Cylindrical, Narrow, Cylindrical, Wide) and bar doors (Rectangular, Wide, Rectangular, Narrow). Ensuring that the door handle could be used by as many people as possible , each door handle is affixed with M4 countersunk screws (ISO 10642), a common household screw. Feedback was received from early users which helped to improve the design, for example, if the handle was rotating too far in use, the design could be adjusted, or if the handle snapped, revealing a stress point, the instructions for the direction of printing could be changed. Further door handles were subsequently created as relationships with users developed, for example, a door handle for vertical hydraulic bars was requested by bakeries.

The team created a specific design for spherical knob handles (Spherical, Moving, Large), most commonly used in North America, and although it is the only door handle opener not for sale online as it is more expensive to hold as inventory due to the volume of the plastic and technical complexity involved in printing. The .STL files are free to download for users to print themselves with guidance on the strongest materials to use. This design for spherical knob handles was one of the more challenging for the team, due to the challenge of gaining the right traction to turn a spherical handle.

The 3D-printed door handle openers join the collection as an example of rapid prototyping at a time of crisis, when designers and engineers use additive manufacturing to quickly tackle complex problems surrounding barriers to health and wellbeing in the built and medical environment. They join the museum’s growing collection of 3D-printed design, including the Gynepunk 3D-printed speculum (CD.20-2020), the 3D-printed gun ‘The Liberator’ (CD.40-2014), ‘Radical Love’ by Heather Dewey Hagborg (CD.28-2018) and the ECAL Digital Market (CD.22-62-2020, furthering our understanding of additive manufacturing in contemporary design practice today.

These door handle openers also serve to highlight the inaccessibility of current interior and industrial design, as their function enables access to other users, such as disabled people that might need to adapt doors to better work for them. This demonstrates where a design not originally intended for disabled users can be appropriated for the needs of those that might benefit from the adaptations it can provide. An accompanying object in the collection, although designed initially specifically for disabled users, is the Yard-arm pick-up stick by DA Morton (CIRC.19-1966). This pick-up stick highlights the inadequacies of the built and domestic environment for disabled people, while also going on to become popular in wider use for non-disabled individuals, for example in its use in hygiene environments where the ability to distance oneself from potentially harmful material is important.

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 2 parts. (Some alternative part names are also shown below)

|

| Materials and techniques | Manufactured from Nylon PA 12, a fine polyamide powder. |

| Brief description | 3D printed door handle by Materialise, of type 'Cylindrical, Narrow'. |

| Dimensions | |

| Credit line | Materialise |

| Summary | These are a set of 3D-printed door handle openers from Materialise, created to enable users to open doors without touching them with their hands. They are a design response to a new need at the time of the COVID-19 pandemic when surfaces were understood to be sites widespread transmission of the virus. Materialise was founded in 1990 in Leuven in Belgium by design couple Hilde Ingelaere and Wilfried Vancraen to rapid prototype. This is a process where designers quickly fabricate a design a scale model of a physical part or assembly using three-dimensional computer aided design through 3D printing. Ingelaere and Vancraen went on to create 3D-printing software, platforms and services for industries such as healthcare – including producing anatomical models for doctors using CT (computed tomography) image data and models for full face transplants – automotive and aerospace, art and design, and consumer goods. They also created one of the first online ordering services ‘Materialise OnSite’ in 1997 to allow users to print designs, even if they did not have a high specification printer themselves. Later, in 2009, Materialise created i.materialise, where users could upload, sell, print and share their own designs with others. Materialise’s 3D-printed door handle openers were in extensive use during the pandemic in hospitals, care homes and in hospitality with the aim to prevent contamination through touching. Attached to door handles with screws, users could open a door handle by pulling or pushing with an elbow or arm, rather than a hand, avoiding contact with a surface that may have been previously contaminated by another person who may have come into contact with COVID-19. The 3D-printed door handle openers are fabricated using laser-sintering (which allows for mass production) or in multi-jet fusion (which allows precision and accuracy) in Nylon PA12, created from a fine polyamide powder. This material is often used because of its low cost and high precision, it also has chemical resistance and limited moisture absorption, making it ideal for a project such as this in which the ability to clean the door handles effectively is important. PA12 is also commonly used in bioengineering, such as in the application of implants. The openers are fitted to existing doorhandles and, Materialise explain that the openers themselves are dishwasher safe once screws have been removed. The door handle openers were first conceived during a company ‘sprint’ – a term originating from ‘agile’ software development in which a product is created, iterated, tested and produced in a short set period of time – to improve the working conditions in Materialise’s workshops and offices. This effort was partly in response to a study published on 17 March 2020 in the New England Journal of Medicine which confirmed that coronavirus remains active on surfaces such as plastic and stainless steel for up to 72 hours. The first design was made without screws and clipped together, and although it seemed ergonomically optimised, it would have been expensive to print due to the specific material needed to support the weight, the volume of the material needed, and required use of more expensive 3D printers that would have prohibited access to many that needed the handles. Due to these challenges, this design did not make it to the final stages of production. Instead, the team took lessons from the initial sprint session and focused on a design that didn’t need as much support structure in the printing process (extra structure produced during printing to support the item being produced as it is produced), and therefore were less wasteful. In all it took the Materialise team 24 hours to create, test and validate the door handle before they were able to upload the open-source designs to be downloaded for free on their platforms. The designs were also available online to purchase as a set of two ready-printed openers from the company website, accompanied with a sticker bearing the slogan “Do No Harm, Use Your Arm!”. Following the initial sprint, the Materialise team then expanded on the first design to create a set of openers that would fit on a number of common door handles, such as lever (Cylindrical, Narrow, Cylindrical, Wide) and bar doors (Rectangular, Wide, Rectangular, Narrow). Ensuring that the door handle could be used by as many people as possible , each door handle is affixed with M4 countersunk screws (ISO 10642), a common household screw. Feedback was received from early users which helped to improve the design, for example, if the handle was rotating too far in use, the design could be adjusted, or if the handle snapped, revealing a stress point, the instructions for the direction of printing could be changed. Further door handles were subsequently created as relationships with users developed, for example, a door handle for vertical hydraulic bars was requested by bakeries. The team created a specific design for spherical knob handles (Spherical, Moving, Large), most commonly used in North America, and although it is the only door handle opener not for sale online as it is more expensive to hold as inventory due to the volume of the plastic and technical complexity involved in printing. The .STL files are free to download for users to print themselves with guidance on the strongest materials to use. This design for spherical knob handles was one of the more challenging for the team, due to the challenge of gaining the right traction to turn a spherical handle. The 3D-printed door handle openers join the collection as an example of rapid prototyping at a time of crisis, when designers and engineers use additive manufacturing to quickly tackle complex problems surrounding barriers to health and wellbeing in the built and medical environment. They join the museum’s growing collection of 3D-printed design, including the Gynepunk 3D-printed speculum (CD.20-2020), the 3D-printed gun ‘The Liberator’ (CD.40-2014), ‘Radical Love’ by Heather Dewey Hagborg (CD.28-2018) and the ECAL Digital Market (CD.22-62-2020, furthering our understanding of additive manufacturing in contemporary design practice today. These door handle openers also serve to highlight the inaccessibility of current interior and industrial design, as their function enables access to other users, such as disabled people that might need to adapt doors to better work for them. This demonstrates where a design not originally intended for disabled users can be appropriated for the needs of those that might benefit from the adaptations it can provide. An accompanying object in the collection, although designed initially specifically for disabled users, is the Yard-arm pick-up stick by DA Morton (CIRC.19-1966). This pick-up stick highlights the inadequacies of the built and domestic environment for disabled people, while also going on to become popular in wider use for non-disabled individuals, for example in its use in hygiene environments where the ability to distance oneself from potentially harmful material is important. |

| Collection | |

| Accession number | CD.35-2021 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | April 21, 2021 |

| Record URL |

Download as: JSONIIIF Manifest