Adidas x Parley trainers

Adidas X Parley Trainers

2015

2015

| Artist/Maker |

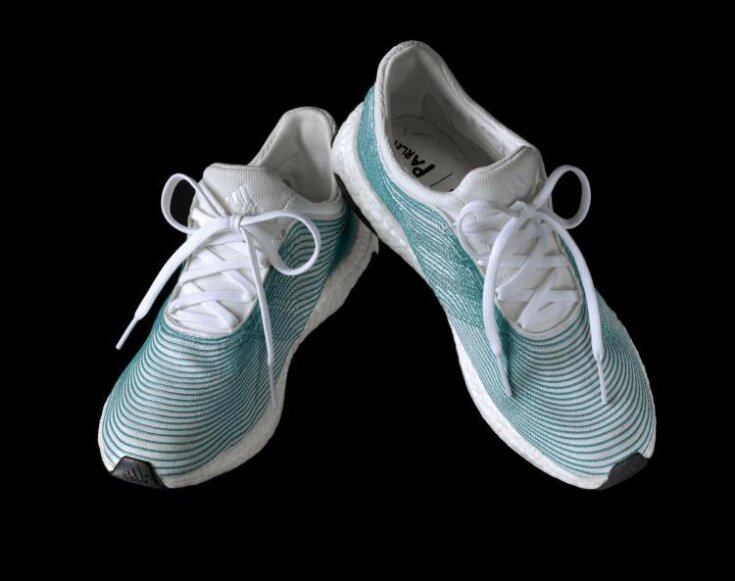

These Adidas x Parley trainers were designed by Alexander Taylor in 2015. The process of making the shoe – which incorporates a special weaving technique called ‘tailored fibre placement’ which enables the use of the recycled plastic – was brought about by partnerships facilitated by Adidas with the goal of making a shoe composed of ocean waste.

As Taylor explained in an interview with ‘Design: 1900 to Now’ gallery curators Corinna Gardner and Johanna Agerman Ross, Adidas had been looking for partners in other industries in the run up to the 2016 Olympics. One of the partnerships they formed was with ‘Parley for the Ocean’, a charity founded by Cyril Goodge, that collaborates with creatives to help solve the problem of plastics in the oceans. The charity’s website explains: “Parley is the space where creators, thinkers, and leaders come together to raise awareness for the beauty and fragility of our oceans and collaborate on projects that can end their destruction”.

Parley in turn collaborated with a non-profit organisation called Sea Shepherd, founded by Captain Paul Watson with the goal of protecting marine life. The material Taylor used for the shoes had been intercepted by Sea Shepherd off the coast of West Africa. The net was 72 km long, 2km wide, and took Sea Shepherd boat crew five weeks to pull out of the ocean by hand. Thunder, the illegal poaching vessel that was responsible for the nets, was pursued by Sea Shepherd for 110 days, before the ship was intentionally sunk by the crew in 2015. The crew were rescued by Sea Shepherd, and the captain and two crew members were imprisoned and fined 15 million euros by the island state of São Tomé and Príncipe. Later, in 2018, the owner of Thunder, was fined 8.2 million euros in a civil case brought by the Spanish government.

The simplified construction of the shoe allows for the more sustainable processes to be employed. The wave design of the shoe was driven by the limits of the technology, and the most efficient way to lay down the material. Taylor wanted to keep the shoe clean of a logo and expressed surprise at the success of getting this proposal past the marketing team. This is testament to the priorities of the brand shifted - at least in the context of this project – from a focus on profit and brand recognition, to innovative use of recycled materials.

Two pairs of shoes were presented at the United Nations launch. They were not a finished product in terms of a high-performance sports shoe, but rather, as Taylor described them, “a statement of intent”. Following the launch, 50 pairs were made – these shoes are part of this first run – and were not for sale but were won by people demonstrating their commitment to Ocean clean-up. People submitted videos of themselves cleaning beaches, recycling, and making pledges, and when the winners were chosen, the shoes were made to order. Following a second run of 50 pairs, a more traditional knitting technique was used to scale production. They were produced for a mass market in 2017, and the partnership has continued until the time of writing, indicating the success of the project.

As Taylor explained in an interview with ‘Design: 1900 to Now’ gallery curators Corinna Gardner and Johanna Agerman Ross, Adidas had been looking for partners in other industries in the run up to the 2016 Olympics. One of the partnerships they formed was with ‘Parley for the Ocean’, a charity founded by Cyril Goodge, that collaborates with creatives to help solve the problem of plastics in the oceans. The charity’s website explains: “Parley is the space where creators, thinkers, and leaders come together to raise awareness for the beauty and fragility of our oceans and collaborate on projects that can end their destruction”.

Parley in turn collaborated with a non-profit organisation called Sea Shepherd, founded by Captain Paul Watson with the goal of protecting marine life. The material Taylor used for the shoes had been intercepted by Sea Shepherd off the coast of West Africa. The net was 72 km long, 2km wide, and took Sea Shepherd boat crew five weeks to pull out of the ocean by hand. Thunder, the illegal poaching vessel that was responsible for the nets, was pursued by Sea Shepherd for 110 days, before the ship was intentionally sunk by the crew in 2015. The crew were rescued by Sea Shepherd, and the captain and two crew members were imprisoned and fined 15 million euros by the island state of São Tomé and Príncipe. Later, in 2018, the owner of Thunder, was fined 8.2 million euros in a civil case brought by the Spanish government.

The simplified construction of the shoe allows for the more sustainable processes to be employed. The wave design of the shoe was driven by the limits of the technology, and the most efficient way to lay down the material. Taylor wanted to keep the shoe clean of a logo and expressed surprise at the success of getting this proposal past the marketing team. This is testament to the priorities of the brand shifted - at least in the context of this project – from a focus on profit and brand recognition, to innovative use of recycled materials.

Two pairs of shoes were presented at the United Nations launch. They were not a finished product in terms of a high-performance sports shoe, but rather, as Taylor described them, “a statement of intent”. Following the launch, 50 pairs were made – these shoes are part of this first run – and were not for sale but were won by people demonstrating their commitment to Ocean clean-up. People submitted videos of themselves cleaning beaches, recycling, and making pledges, and when the winners were chosen, the shoes were made to order. Following a second run of 50 pairs, a more traditional knitting technique was used to scale production. They were produced for a mass market in 2017, and the partnership has continued until the time of writing, indicating the success of the project.

Object details

| Categories | |

| Object type | |

| Title | Adidas x Parley trainers (manufacturer's title) |

| Materials and techniques | The shoe is made from salvaged illegal deep-sea plastic gillnets. The ropes that the net was composed of were washed in washing machines to remove the smell, ground to a powder, and processed by an extrusion machine to make the filament to match the diameters needed for the specialist embroidery machinery. Adidas worked with ‘green’ chemists from the company Bionic textile, who advised on re-processing the plastics, to understand and develop this process |

| Brief description | Adidas x Parley trainers, designed by Alexander Taylor, 2015 |

| Physical description | The trainers are composed of a white, semi-transparent base of Polyethylene terephthalate, with blue/green nylon stitching on the upper made using salvaged illegal deep-sea plastic gillnets removed from the Antarctic Ocean by the charity Sea Shepherd. The sole is the Adidas ‘boost’ sole. |

| Production type | Prototype |

| Gallery label |

|

| Credit line | Given by Adidas |

| Object history | Taylor’s design process for the shoe was condensed into a one-week period, as Adidas wanted to announce their partnership with Parley at a talk during the ‘UN X PARLEY: OCEANS. CLIMATE. LIFE’ event at the United Nations headquarters in New York in June 2015. |

| Association | |

| Summary | These Adidas x Parley trainers were designed by Alexander Taylor in 2015. The process of making the shoe – which incorporates a special weaving technique called ‘tailored fibre placement’ which enables the use of the recycled plastic – was brought about by partnerships facilitated by Adidas with the goal of making a shoe composed of ocean waste. As Taylor explained in an interview with ‘Design: 1900 to Now’ gallery curators Corinna Gardner and Johanna Agerman Ross, Adidas had been looking for partners in other industries in the run up to the 2016 Olympics. One of the partnerships they formed was with ‘Parley for the Ocean’, a charity founded by Cyril Goodge, that collaborates with creatives to help solve the problem of plastics in the oceans. The charity’s website explains: “Parley is the space where creators, thinkers, and leaders come together to raise awareness for the beauty and fragility of our oceans and collaborate on projects that can end their destruction”. Parley in turn collaborated with a non-profit organisation called Sea Shepherd, founded by Captain Paul Watson with the goal of protecting marine life. The material Taylor used for the shoes had been intercepted by Sea Shepherd off the coast of West Africa. The net was 72 km long, 2km wide, and took Sea Shepherd boat crew five weeks to pull out of the ocean by hand. Thunder, the illegal poaching vessel that was responsible for the nets, was pursued by Sea Shepherd for 110 days, before the ship was intentionally sunk by the crew in 2015. The crew were rescued by Sea Shepherd, and the captain and two crew members were imprisoned and fined 15 million euros by the island state of São Tomé and Príncipe. Later, in 2018, the owner of Thunder, was fined 8.2 million euros in a civil case brought by the Spanish government. The simplified construction of the shoe allows for the more sustainable processes to be employed. The wave design of the shoe was driven by the limits of the technology, and the most efficient way to lay down the material. Taylor wanted to keep the shoe clean of a logo and expressed surprise at the success of getting this proposal past the marketing team. This is testament to the priorities of the brand shifted - at least in the context of this project – from a focus on profit and brand recognition, to innovative use of recycled materials. Two pairs of shoes were presented at the United Nations launch. They were not a finished product in terms of a high-performance sports shoe, but rather, as Taylor described them, “a statement of intent”. Following the launch, 50 pairs were made – these shoes are part of this first run – and were not for sale but were won by people demonstrating their commitment to Ocean clean-up. People submitted videos of themselves cleaning beaches, recycling, and making pledges, and when the winners were chosen, the shoes were made to order. Following a second run of 50 pairs, a more traditional knitting technique was used to scale production. They were produced for a mass market in 2017, and the partnership has continued until the time of writing, indicating the success of the project. |

| Collection | |

| Accession number | CD.25-2019 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | October 2, 2018 |

| Record URL |

Download as: JSONIIIF Manifest