Thing-O-Matic

3D Printer

| Artist/Maker |

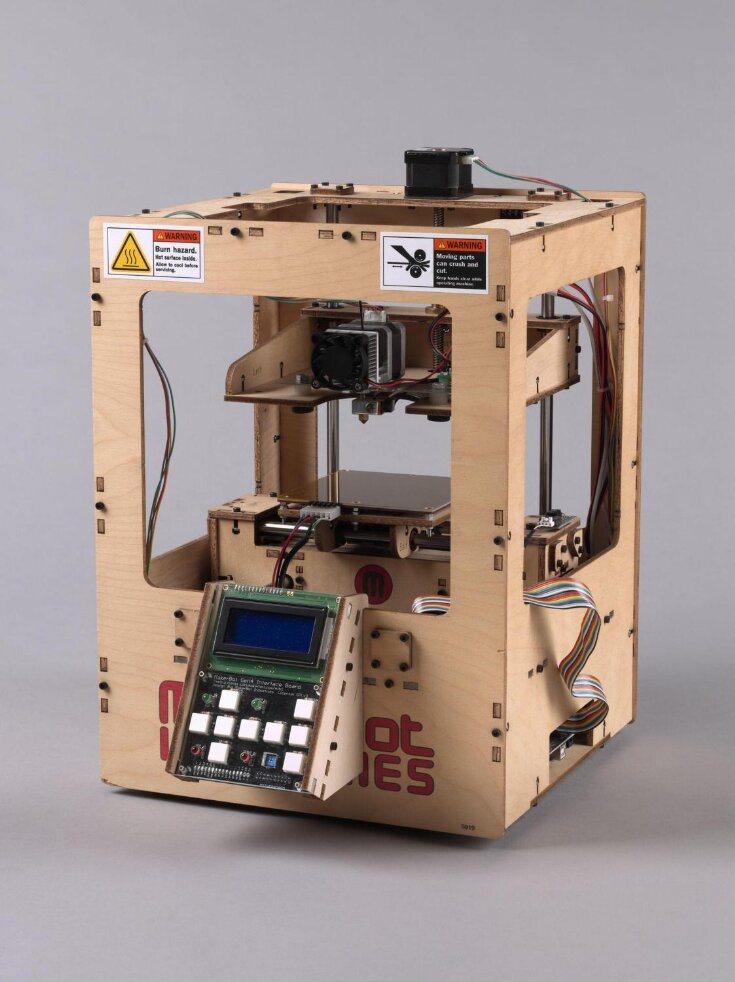

The Thing-O-Matic 3D printer by MakerBot was the first desktop 3D-printer to be widely manufactured at a relatively affordable price for consumers. The Thing-O-Matic was marketed to hobbyists and ‘fab labs’ (Fabrication Labs) rather than to the commercial sector which required larger, higher quality prints.

The Thing-O-Matic 3D printer was introduced by MakerBot in September 2010, at Maker Faire NYC in Queens, at a price of $1225. It was the company’s second release after the Cupcake CNC. The design was open source and files were made available on MakerBot’s object repository Thingiverse. The Thing-O-Matic was discontinued in the spring of 2012, introducing the Replicator in its place. MakerBot is an American desktop 3D printer manufacturer headquartered in New York City. It was founded in January 2009 by Bre Pettis, Adam Mayer, and Zach "Hoeken" Smith to build on the early progress of the RepRap Project.

The Thing-O-Matic exemplified MakerBot’s approach to the open-hardware and open-software, part of the open-source movement, with the entire system designed to be assembled, modified and manipulated by users. Open-source allowed for users to have direct access to the source code and hardware specifications for the Thing-O-Matic, enabling users to modify the printer to their own specifications. For example, users could adjust the outer casing to detach in order to more easily troubleshoot problems, or to extend the build platform to enable larger printed objects. The software for the Thing-O-Matic was often a collaboration between users, with files shared frequently on the Thingiverse community platforms.

The Thing-O-Matic was sold for self-assembly as well as fully assembled at the higher price of $2500. The outer case is made of laser-cut plywood, containing the electronic components and Automated Build Platform (ABP). The Automated Build Platform was an innovation introduced to the Thing-O-Matic, a moveable belt system which allowed for multiple objects to be printed in succession without the need for human intervention, with the machine clearing the build surface between objects in the print queue.

A 3D printer creates objects by extruding layers of plastic onto a platform through a heated nozzle. In the Thing-O-Matic, the build platform moves along the x and y axes relative to a print head. The print head is raised and lowered along the z axis. Parts are fabricated with the Thing-O-Matic using acrylonitrile butadiene styrene (ABS) or polylactic acid (PLA) with an MK7 extrusion head on a z-axis mobility and a plate with x- and y-axis mobility. Objects are printed from the .STL file format (an abbreviation of "stereolithography"), designed with programs including Blender and Sketchup, with many designs available on MakerBot’s Thingiverse website.

The Thing-O-Matic holds importance for the Museum’s collection in evidencing early at-home and hobbyist 3D printing design communities and their link to open-source as a means of innovation. The printer forms part of the museum’s growing collection of objects addressing the issue of 3D printing in contemporary design including the Bolide HR Handlebars, The Liberator, and Radical Love by Heather Dewey Hagborg.

The Thing-O-Matic 3D printer was introduced by MakerBot in September 2010, at Maker Faire NYC in Queens, at a price of $1225. It was the company’s second release after the Cupcake CNC. The design was open source and files were made available on MakerBot’s object repository Thingiverse. The Thing-O-Matic was discontinued in the spring of 2012, introducing the Replicator in its place. MakerBot is an American desktop 3D printer manufacturer headquartered in New York City. It was founded in January 2009 by Bre Pettis, Adam Mayer, and Zach "Hoeken" Smith to build on the early progress of the RepRap Project.

The Thing-O-Matic exemplified MakerBot’s approach to the open-hardware and open-software, part of the open-source movement, with the entire system designed to be assembled, modified and manipulated by users. Open-source allowed for users to have direct access to the source code and hardware specifications for the Thing-O-Matic, enabling users to modify the printer to their own specifications. For example, users could adjust the outer casing to detach in order to more easily troubleshoot problems, or to extend the build platform to enable larger printed objects. The software for the Thing-O-Matic was often a collaboration between users, with files shared frequently on the Thingiverse community platforms.

The Thing-O-Matic was sold for self-assembly as well as fully assembled at the higher price of $2500. The outer case is made of laser-cut plywood, containing the electronic components and Automated Build Platform (ABP). The Automated Build Platform was an innovation introduced to the Thing-O-Matic, a moveable belt system which allowed for multiple objects to be printed in succession without the need for human intervention, with the machine clearing the build surface between objects in the print queue.

A 3D printer creates objects by extruding layers of plastic onto a platform through a heated nozzle. In the Thing-O-Matic, the build platform moves along the x and y axes relative to a print head. The print head is raised and lowered along the z axis. Parts are fabricated with the Thing-O-Matic using acrylonitrile butadiene styrene (ABS) or polylactic acid (PLA) with an MK7 extrusion head on a z-axis mobility and a plate with x- and y-axis mobility. Objects are printed from the .STL file format (an abbreviation of "stereolithography"), designed with programs including Blender and Sketchup, with many designs available on MakerBot’s Thingiverse website.

The Thing-O-Matic holds importance for the Museum’s collection in evidencing early at-home and hobbyist 3D printing design communities and their link to open-source as a means of innovation. The printer forms part of the museum’s growing collection of objects addressing the issue of 3D printing in contemporary design including the Bolide HR Handlebars, The Liberator, and Radical Love by Heather Dewey Hagborg.

Delve deeper

Discover more about this object

Object details

| Category | |

| Object type | |

| Title | Thing-O-Matic (manufacturer's title) |

| Materials and techniques | Electronics, plywood, plastic. |

| Brief description | Thing-O-Matic by MakerBot; A fully assembled 3D printer in a plywood outer structure with electronics, made by MakerBot. |

| Physical description | The outer case for the Thing-o-Matic is made of laser-cut plywood, containing the electronic components and Automated Build Platform (ABP). The Automated Build Platform was an innovation introduced to the Thing-O-Matic, a moveable belt system which allowed for multiple objects to be printed in succession without the need for human intervention, with the machine clearing the build surface between objects in the print queue. |

| Dimensions |

|

| Gallery label | This object sits in the "Data and Communication" section of the Design 1900-Now gallery, opened June 2021

Open-source innovation

The Thing-O-Matic 3D printer can be built using

open-source hardware and runs on open-source

software. All the required parts are either available

off-the-shelf or can be made using plans freely

downloadable online. Aimed at hobbyists, MakerBot

launched the printer at the 2010 New York Maker

Faire. It marked an early, affordable entry into

the 3D printer market.

Self-assembly 3D printer

Thing-O-Matic, 2010

Designed by MakerBot, USA

Laser-cut plywood, plastic and electronic components

Museum no. CD.27-2018 |

| Summary | The Thing-O-Matic 3D printer by MakerBot was the first desktop 3D-printer to be widely manufactured at a relatively affordable price for consumers. The Thing-O-Matic was marketed to hobbyists and ‘fab labs’ (Fabrication Labs) rather than to the commercial sector which required larger, higher quality prints. The Thing-O-Matic 3D printer was introduced by MakerBot in September 2010, at Maker Faire NYC in Queens, at a price of $1225. It was the company’s second release after the Cupcake CNC. The design was open source and files were made available on MakerBot’s object repository Thingiverse. The Thing-O-Matic was discontinued in the spring of 2012, introducing the Replicator in its place. MakerBot is an American desktop 3D printer manufacturer headquartered in New York City. It was founded in January 2009 by Bre Pettis, Adam Mayer, and Zach "Hoeken" Smith to build on the early progress of the RepRap Project. The Thing-O-Matic exemplified MakerBot’s approach to the open-hardware and open-software, part of the open-source movement, with the entire system designed to be assembled, modified and manipulated by users. Open-source allowed for users to have direct access to the source code and hardware specifications for the Thing-O-Matic, enabling users to modify the printer to their own specifications. For example, users could adjust the outer casing to detach in order to more easily troubleshoot problems, or to extend the build platform to enable larger printed objects. The software for the Thing-O-Matic was often a collaboration between users, with files shared frequently on the Thingiverse community platforms. The Thing-O-Matic was sold for self-assembly as well as fully assembled at the higher price of $2500. The outer case is made of laser-cut plywood, containing the electronic components and Automated Build Platform (ABP). The Automated Build Platform was an innovation introduced to the Thing-O-Matic, a moveable belt system which allowed for multiple objects to be printed in succession without the need for human intervention, with the machine clearing the build surface between objects in the print queue. A 3D printer creates objects by extruding layers of plastic onto a platform through a heated nozzle. In the Thing-O-Matic, the build platform moves along the x and y axes relative to a print head. The print head is raised and lowered along the z axis. Parts are fabricated with the Thing-O-Matic using acrylonitrile butadiene styrene (ABS) or polylactic acid (PLA) with an MK7 extrusion head on a z-axis mobility and a plate with x- and y-axis mobility. Objects are printed from the .STL file format (an abbreviation of "stereolithography"), designed with programs including Blender and Sketchup, with many designs available on MakerBot’s Thingiverse website. The Thing-O-Matic holds importance for the Museum’s collection in evidencing early at-home and hobbyist 3D printing design communities and their link to open-source as a means of innovation. The printer forms part of the museum’s growing collection of objects addressing the issue of 3D printing in contemporary design including the Bolide HR Handlebars, The Liberator, and Radical Love by Heather Dewey Hagborg. |

| Collection | |

| Accession number | CD.27-2018 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | May 16, 2018 |

| Record URL |

Download as: JSONIIIF Manifest