Trainers

2017

| Artist/Maker | |

| Place of origin |

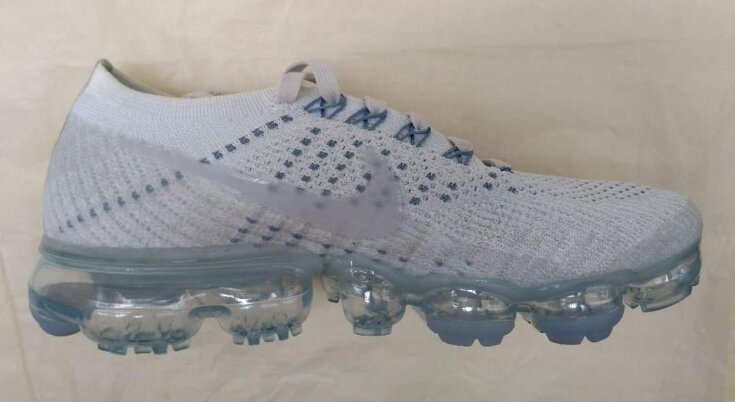

These Air Vapormax Flyknit trainers combine two key developments by Nike designers in one trainer.

Nike began working on ‘Flyknit’ technology in 2007. After five years of development and 195 rounds of adjustments, trainers made with the new technology were first worn at the 2012 Olympics by Somalia-American long-distance runner Abdi Abdirahman. The Flyknit technology allows Nike designers to micro-engineer every stitch of the shoe’s upper, scientifically tuned to meet the exact specifications of athletes. It features an upper knit with a super-light, strong fabric, without the weighty structure of traditional shoe making. The pattern is created via a computer program, which allows for infinite subtle, immediate and specific customisation. It is also a far more sustainable method of manufacture than conventional trainer production as instead of cutting irregular shapes from a rectangular cloth, each Flyknit upper is knitted exactly to size resulting in very minimal waste.

The VaporMax sole was designed to allow Nike to create air bubbles in the sole without having to have a secondary layer of rubber and foam. This gives greater flexibility and spring without compromising on structure, while also reducing weight and waste.

Nike began working on ‘Flyknit’ technology in 2007. After five years of development and 195 rounds of adjustments, trainers made with the new technology were first worn at the 2012 Olympics by Somalia-American long-distance runner Abdi Abdirahman. The Flyknit technology allows Nike designers to micro-engineer every stitch of the shoe’s upper, scientifically tuned to meet the exact specifications of athletes. It features an upper knit with a super-light, strong fabric, without the weighty structure of traditional shoe making. The pattern is created via a computer program, which allows for infinite subtle, immediate and specific customisation. It is also a far more sustainable method of manufacture than conventional trainer production as instead of cutting irregular shapes from a rectangular cloth, each Flyknit upper is knitted exactly to size resulting in very minimal waste.

The VaporMax sole was designed to allow Nike to create air bubbles in the sole without having to have a secondary layer of rubber and foam. This gives greater flexibility and spring without compromising on structure, while also reducing weight and waste.

Object details

| Category | |

| Object type | |

| Parts | This object consists of 2 parts.

|

| Materials and techniques | Polyester, rubber and plastic |

| Brief description | Air Vapormax Flyknit trainers by Nike, polyester, rubber and plastic, designed in USA, made in Vietnam, 2017 |

| Physical description | Air Vapormax Flyknit trainers of grey knitted uppers and transparent rubber sole. |

| Dimensions |

|

| Production type | Mass produced |

| Credit line | Given by Mark Parker |

| Summary | These Air Vapormax Flyknit trainers combine two key developments by Nike designers in one trainer. Nike began working on ‘Flyknit’ technology in 2007. After five years of development and 195 rounds of adjustments, trainers made with the new technology were first worn at the 2012 Olympics by Somalia-American long-distance runner Abdi Abdirahman. The Flyknit technology allows Nike designers to micro-engineer every stitch of the shoe’s upper, scientifically tuned to meet the exact specifications of athletes. It features an upper knit with a super-light, strong fabric, without the weighty structure of traditional shoe making. The pattern is created via a computer program, which allows for infinite subtle, immediate and specific customisation. It is also a far more sustainable method of manufacture than conventional trainer production as instead of cutting irregular shapes from a rectangular cloth, each Flyknit upper is knitted exactly to size resulting in very minimal waste. The VaporMax sole was designed to allow Nike to create air bubbles in the sole without having to have a secondary layer of rubber and foam. This gives greater flexibility and spring without compromising on structure, while also reducing weight and waste. |

| Collection | |

| Accession number | T.19:1, 2-2018 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | January 11, 2018 |

| Record URL |

Download as: JSONIIIF Manifest