Furnishing Fabric

1770-1789 (made)

| Artist/Maker | |

| Place of origin |

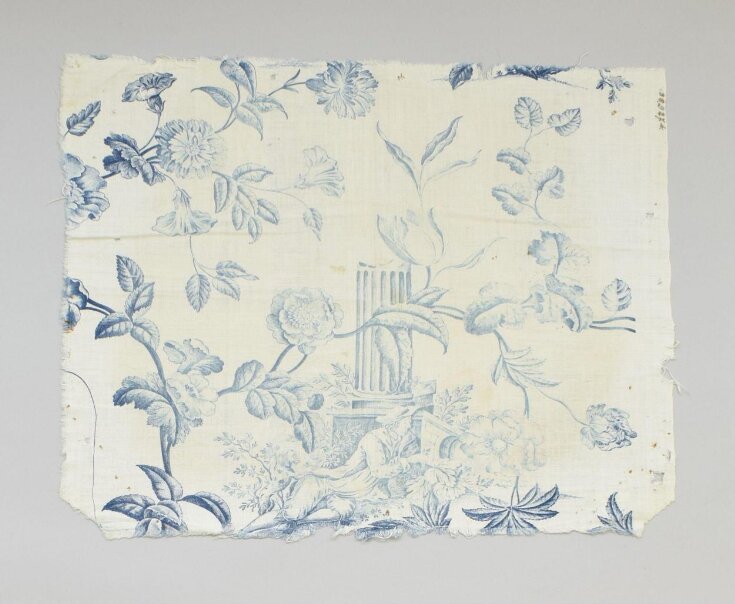

This furnishing fabric, originally a chair seat cover, was printed using an engraved copper plate. The introduction of copper-plate printing in the 1750s meant new possibilities in the development of printed textile design, allowing a fineness of detail and delicacy of drawing which had not been achieved in earlier wood-block printed textiles.

Francis Nixon was a pioneering printer who, at the Drumcondra Printworks near Dublin in 1752, was the first to use copper plates successfully. By 1757 he had moved to England, joining George Amyand in his calico-printing factory at Phippsbridge in Surrey. The partnership continued until their deaths in the mid 1760s, and the firm continued as Nixon & Company, until 1789.

China blue, which has been used here, was a complex process for printing with indigo known abroad as 'English blue'. It gave beautiful fast blues, but by a technique that could not be used with those needed for other colours, so 'pencilling' (hand-painting) of indigo was still needed for polychrome designs. The indigo was printed directly onto the cloth by plate or block as a finely-ground paste. The cloth was then immersed alternately in baths of lime (to dissolve the indigo) and iron-sulphate (to reduce it) as many times as was necessary to achieve the desired strength of blue.

Francis Nixon was a pioneering printer who, at the Drumcondra Printworks near Dublin in 1752, was the first to use copper plates successfully. By 1757 he had moved to England, joining George Amyand in his calico-printing factory at Phippsbridge in Surrey. The partnership continued until their deaths in the mid 1760s, and the firm continued as Nixon & Company, until 1789.

China blue, which has been used here, was a complex process for printing with indigo known abroad as 'English blue'. It gave beautiful fast blues, but by a technique that could not be used with those needed for other colours, so 'pencilling' (hand-painting) of indigo was still needed for polychrome designs. The indigo was printed directly onto the cloth by plate or block as a finely-ground paste. The cloth was then immersed alternately in baths of lime (to dissolve the indigo) and iron-sulphate (to reduce it) as many times as was necessary to achieve the desired strength of blue.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Plate printed cotton |

| Brief description | Furnishing fabric of plate printed cotton, printed by Nixon & Company, England, 1770-1789. |

| Physical description | Furnishing fabric of plate printed cotton in china blue on a white ground. With a design of a man and dog by the base of ruined column surrounded with meandering flowers. Selvedge on right edge. Inked number 38.927b, which was inventory number for Nordiska Museet. There are nail holes and fading, consistent with the textile having been used as a chair cover. |

| Dimensions |

|

| Marks and inscriptions | '38.927b' Note Inked inventory number for Nordiska Museet |

| Credit line | Given by the Nordiska Museet |

| Subjects depicted | |

| Summary | This furnishing fabric, originally a chair seat cover, was printed using an engraved copper plate. The introduction of copper-plate printing in the 1750s meant new possibilities in the development of printed textile design, allowing a fineness of detail and delicacy of drawing which had not been achieved in earlier wood-block printed textiles. Francis Nixon was a pioneering printer who, at the Drumcondra Printworks near Dublin in 1752, was the first to use copper plates successfully. By 1757 he had moved to England, joining George Amyand in his calico-printing factory at Phippsbridge in Surrey. The partnership continued until their deaths in the mid 1760s, and the firm continued as Nixon & Company, until 1789. China blue, which has been used here, was a complex process for printing with indigo known abroad as 'English blue'. It gave beautiful fast blues, but by a technique that could not be used with those needed for other colours, so 'pencilling' (hand-painting) of indigo was still needed for polychrome designs. The indigo was printed directly onto the cloth by plate or block as a finely-ground paste. The cloth was then immersed alternately in baths of lime (to dissolve the indigo) and iron-sulphate (to reduce it) as many times as was necessary to achieve the desired strength of blue. |

| Collection | |

| Accession number | T.384-1998 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | February 9, 2007 |

| Record URL |

Download as: JSONIIIF Manifest