Plato

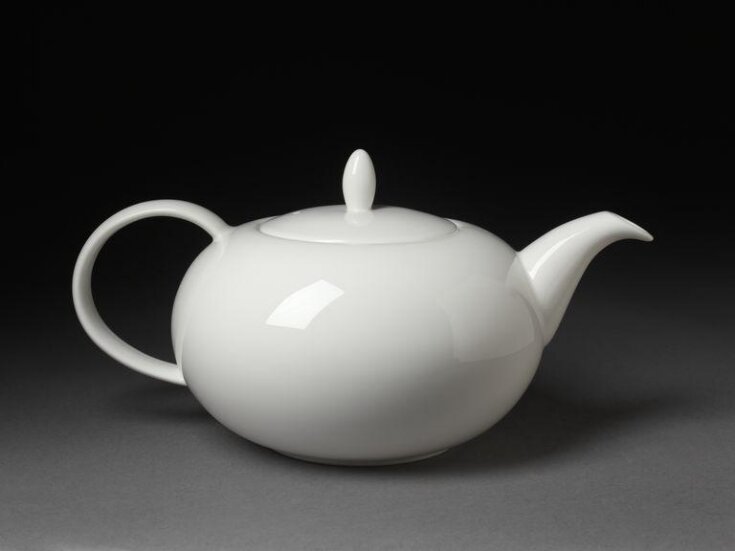

Teapot

2004 (designed), 2007 (made)

2004 (designed), 2007 (made)

| Artist/Maker | |

| Place of origin |

Technological developments since the 1980s have radically changed tableware production. Isostatic pressing, in which granulate clay is moulded under pressure, is now widely used for large production runs of flat or open wares, such as plates and bowls.

High-pressure casting, in which slip (liquid clay) is cast between polymer moulds, can be used for smaller runs. Neither is restricted to making circular shapes. Both are fully automated, fast and precise and result in very few 'seconds' or imperfect wares.

The tablewares in the 'Plato' range were made using various traditional and modern methods: isostatic pressing (plates and saucer), high-pressure casting (rectangular platter), jiggering (bowls and cup) and slip-casting (tea-wares and cup handle).

High-pressure casting, in which slip (liquid clay) is cast between polymer moulds, can be used for smaller runs. Neither is restricted to making circular shapes. Both are fully automated, fast and precise and result in very few 'seconds' or imperfect wares.

The tablewares in the 'Plato' range were made using various traditional and modern methods: isostatic pressing (plates and saucer), high-pressure casting (rectangular platter), jiggering (bowls and cup) and slip-casting (tea-wares and cup handle).

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 2 parts.

|

| Title | Plato (manufacturer's title) |

| Materials and techniques | Bone china, slip-cast |

| Brief description | Teapot, bone china, 'Plato' tableware, designed by Martin Hunt for Queensberry Hunt, 2004, made by Josiah Wedgwood & Sons, Barlaston, 2007. |

| Physical description | Undecorated white bone china. Slip-cast. |

| Dimensions |

|

| Gallery label |

|

| Credit line | Given by WWRD United Kingdom Ltd. |

| Summary | Technological developments since the 1980s have radically changed tableware production. Isostatic pressing, in which granulate clay is moulded under pressure, is now widely used for large production runs of flat or open wares, such as plates and bowls. High-pressure casting, in which slip (liquid clay) is cast between polymer moulds, can be used for smaller runs. Neither is restricted to making circular shapes. Both are fully automated, fast and precise and result in very few 'seconds' or imperfect wares. The tablewares in the 'Plato' range were made using various traditional and modern methods: isostatic pressing (plates and saucer), high-pressure casting (rectangular platter), jiggering (bowls and cup) and slip-casting (tea-wares and cup handle). |

| Collection | |

| Accession number | C.278:1, 2-2009 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | February 1, 2011 |

| Record URL |

Download as: JSON