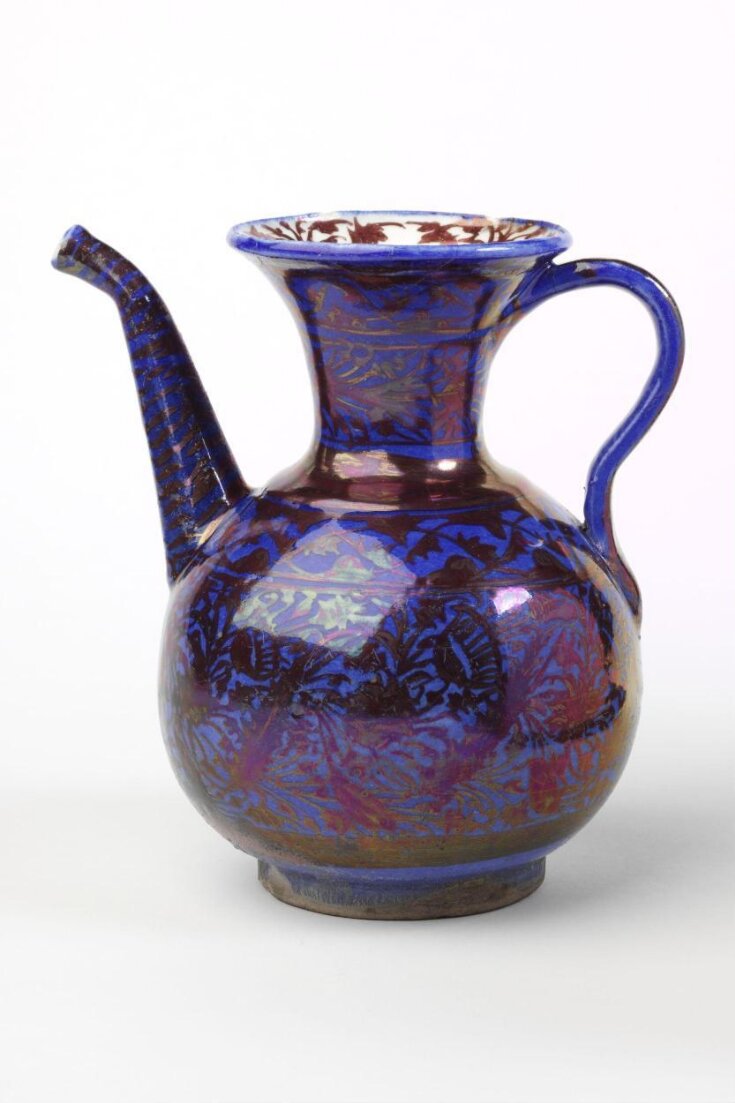

Ewer

late 17th century (made)

| Artist/Maker | |

| Place of origin |

The decoration on this ewer is a combination of dense lustre over clear and cobalt blue glazes. This is a feature of many lustre wares produced in Iran during the period 1650-1700.

Around 1650, a group of Iranian potters revived the technique of lustre decoration. First the potter made a glazed vessel or tile with little or no decoration in the normal way. When the piece had cooled, the potter painted a design over the glaze in metallic compounds. The pot or tile was then fired again, this time with a restricted supply of oxygen. In these conditions, the metallic compounds broke down, and a thin deposit of copper or silver was left on the surface of the glaze. When polished, this surface layer reflected the light.

This technique had not been used on any scale in Iran for three centuries. We do not know how the technique was revived, or where the potters produced their distinctive wares.

Around 1650, a group of Iranian potters revived the technique of lustre decoration. First the potter made a glazed vessel or tile with little or no decoration in the normal way. When the piece had cooled, the potter painted a design over the glaze in metallic compounds. The pot or tile was then fired again, this time with a restricted supply of oxygen. In these conditions, the metallic compounds broke down, and a thin deposit of copper or silver was left on the surface of the glaze. When polished, this surface layer reflected the light.

This technique had not been used on any scale in Iran for three centuries. We do not know how the technique was revived, or where the potters produced their distinctive wares.

Object details

| Category | |

| Object type | |

| Materials and techniques | Fritware, underglaze and lustre decoration |

| Brief description | Ewer decorated in cobalt and lustre, Iran, late 17th century. |

| Physical description | Deep cobalt blue lustre jug. Rounded body narrowing to neck with flared rim. The spout of the jug is set on the shoulder and curves gently at the tip. The handle starts right under the rim of the jug and curves slightly inwards before meeting the shoulder of the base. The lustre is a deep ruby red. In ceramic production, compounds of copper and silver were used to create the shiny, metallic decoration known as lustre. It was a two-stage process. In the first stage, the glazed pot was produced in the normal way by firing in a kiln. In the second, a design was painted over the glaze using the metallic compounds, and the pot was refired at a lower temperature in a kiln with a restricted supply of oxygen. During this second firing, the heat converted the metallic compounds into oxides, and the carbon monoxide produced by the fire then drew the oxygen out of the oxides, leaving the metal as a thin deposit on the vessel. The result was a surface with an attractive golden glow. Both these forms of decoration - blue-and-white and lustre - were to have a very long history, and they are both still in use today. |

| Dimensions |

|

| Style | |

| Gallery label |

|

| Historical context | The designs of Safavid lustre owe nothing to the Chinese, but are purely Iranian. Their source is not precisely identifiable, the motifs are a mixture of the sort of decoration found in contemporary manuscript illumination, see Pope (1939; pls 892-93, 896-98. 974-75 etc.) and designs developed specifically for ceramics, such as the arabesques and floral designs found on slip-painted wares (cat. U.25.U26). The relationship ends there though. The range of shapes, the materials and details of making indicate that it is a separate production. |

| Summary | The decoration on this ewer is a combination of dense lustre over clear and cobalt blue glazes. This is a feature of many lustre wares produced in Iran during the period 1650-1700. Around 1650, a group of Iranian potters revived the technique of lustre decoration. First the potter made a glazed vessel or tile with little or no decoration in the normal way. When the piece had cooled, the potter painted a design over the glaze in metallic compounds. The pot or tile was then fired again, this time with a restricted supply of oxygen. In these conditions, the metallic compounds broke down, and a thin deposit of copper or silver was left on the surface of the glaze. When polished, this surface layer reflected the light. This technique had not been used on any scale in Iran for three centuries. We do not know how the technique was revived, or where the potters produced their distinctive wares. |

| Bibliographic reference | Watson, Oliver, Ceramics from Islamic Lands: Kuwait National Museum: The Al-Sabah Collections; London Thames & Hudson, 2004

Stanley, Tim: Palace and Mosque: Islamic Art from the Middle East, V & A Publications 2004

Caiger-Smith, Alan Lustre Pottery: Technique, Tradition and Innovation in Islam and the Western World London, 1985. P.197) |

| Collection | |

| Accession number | 924-1876 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | February 24, 2005 |

| Record URL |

Download as: JSONIIIF Manifest