Armchair

1580-1620 (made)

| Artist/Maker | |

| Place of origin |

Object Type

Three-legged chairs were suitable for use on uneven floors as they would not wobble. In their simplest form turned seats were stools made by inserting three splayed legs into holes in a flat piece of wood.

Materials & Making

Chairs like this and other objects turned on a lathe were sometimes called 'thrown'. They were made on a pole lathe, driven by pulling on a length of cord attached to a pole. The post was attached to a spindle, which was turned by the cord. It was shaped and patterned by a gouge, or cutting tool, held against the post as it turned. Pole lathes were simple to make and could be set up anywhere.

These chairs were often made from locally grown wood, in this case freshly cut oak, a tree native to Britain. The wood has since been varnished black.

Time

Turned armchairs and three-legged stools can be seen in medieval manuscripts, though they probably were made even earlier. Similar chairs were also made in other parts of Northern Europe and Scandinavia. They are difficult to date accurately, but in Britain many were made in the 16th and 17th centuries. We think this one dates from that time.

Three-legged chairs were suitable for use on uneven floors as they would not wobble. In their simplest form turned seats were stools made by inserting three splayed legs into holes in a flat piece of wood.

Materials & Making

Chairs like this and other objects turned on a lathe were sometimes called 'thrown'. They were made on a pole lathe, driven by pulling on a length of cord attached to a pole. The post was attached to a spindle, which was turned by the cord. It was shaped and patterned by a gouge, or cutting tool, held against the post as it turned. Pole lathes were simple to make and could be set up anywhere.

These chairs were often made from locally grown wood, in this case freshly cut oak, a tree native to Britain. The wood has since been varnished black.

Time

Turned armchairs and three-legged stools can be seen in medieval manuscripts, though they probably were made even earlier. Similar chairs were also made in other parts of Northern Europe and Scandinavia. They are difficult to date accurately, but in Britain many were made in the 16th and 17th centuries. We think this one dates from that time.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Unseasoned ('green') oak |

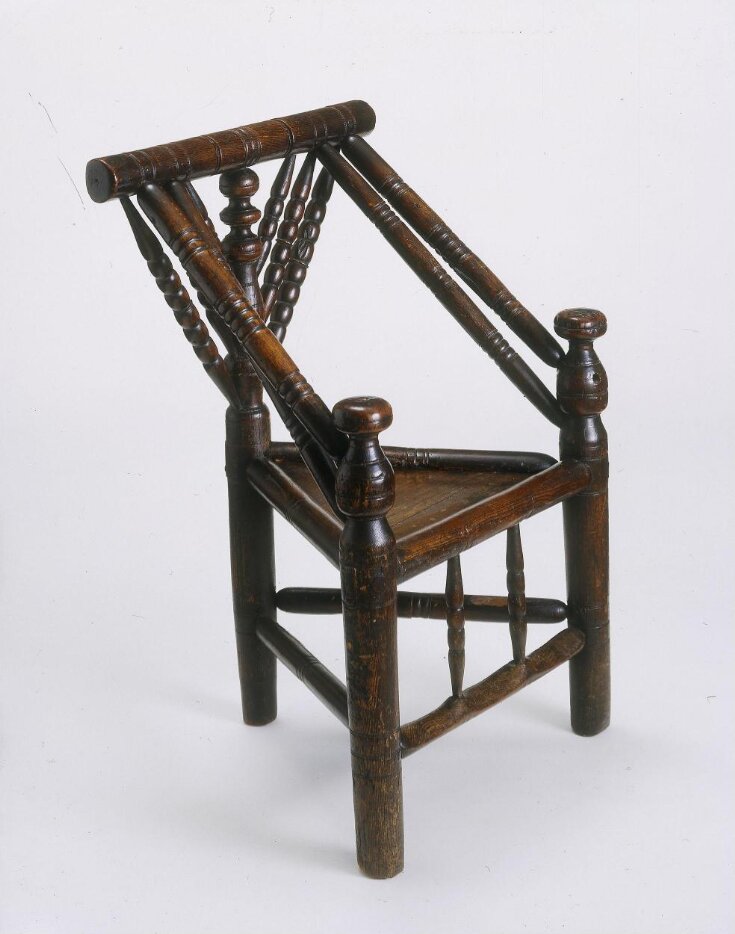

| Brief description | Three-legged turned oak armchair, English, 1580-1620 |

| Physical description | Turned, triangular oak armchair. In the centre of the back is a vertical upright with a series of deep rings and baluster shape turnings above the seat, from which three turned spindles rise diagonally on either side to meet the top rail. The arms which are each composed of two ringed spindles, slope downward from the back and are 'housed' in the handles (or finials) which are turned with an inverted baluster below a ‘bun’. The triangular board seat is housed in the rails. There are three turned stretchers, the front stretcher linked to the seat rail by two vertical spindles. Turnings There are three styles of ornamental turning: the larger elements (three vertical posts, top rail, three seat rails and two of the side stretchers) have shallow incised lines at regular intervals, sometimes lining up with the joints. The subsidiary elements (four arms pieces, six diagonal back spindles and two spindles between the front rails) are turned with deeper rings. The lower front rail is plain. Construction The chair is joined using round mortise and tenon joints, the main elements single-pegged, others (the front vertical spindles, the back diagonal spindles and the inner arm piece) without pegs. The larger elements show moderate oval shrinkage (eg 2-3mm across 7cm) indicating that the wood was turned part-seasoned. Where the front uprights meet the side rails the rails terminate in round tenons which pass through the larger, pierced, rectangular tenons at both ends of the front rail. At the back upright, in the same way, one side rail with round tenon passes through the rectangular tenon of the other side rail. Where the stretchers (all with round tenons) meet the uprights, the side stretchers are offset above the front stretcher, and the right side rail is angled so that it joins the upright above the left side rail joint. Lathe pintle holes are visible at both ends of the top rail. In both handles are fragments of iron nails. The board seat consists of three, thin oak boards (one with flaking paint or dark varnish), presumably glued together, which sit in a deep groove run on the inside of each rail: the widest, front board appears to be riven, with chamfered edges, whereas the other boards appear to have been planed smooth. Modifications Front right upright (at the baluster shape) has an open dowel hole (purpose unclear). Back upright has been tipped 6.5cm The joint between front seat rail and the front left upright has been wedged, and there is evidence that the left rail tenon has been repaired - suggesting that the joint may have been dismantled - probably to replace or repair the seat board. Noticeable rubbing wear on the seat rails, front stretcher and on the handles. A darkened, dirty varnish overall, with some flaking under the seat. |

| Dimensions |

|

| Gallery label | British Galleries:

This chair was made almost entirely of turned posts with simple joints. The posts were worked on a lathe, a foot-operated machine that turned a length of wood at high speed, while the turner shaped it, using a chisel. The front 'stretcher' under the seat has often been used as a foot rest and shows the wear of thousands of feet.(27/03/2003) |

| Credit line | Given by Mrs C. E. Allan OBE, in memory of her husband, Mr C. E. Allan |

| Object history | Probably made in Britain, by an unindentified turner. Turned chair at Tamworth, gift of Mrs C E Allan, Avalon, St Albans, 29.IV.31 Notes from R.P. 31/4310 Gift Form Lists, among 11 items, as "1 Chair, oak turned" 24/4/31 Ralph Edwards visited St Albans to view the objects offered on loan with the suggestion of an ultimate gift by Mrs Allan of furniture collected by her late husband. Mrs Allan then offers the furniture as an outright gift. Edwards notes: "her husband was a friend of the late Seymour Lucas and acquired a number of good pieces of oak furniture many years ago. Among the objects now offered….an early oak chair….." Edwards lists the furniture he thinks should be collected. Among items from the Hall is "oak turned chair". 6/5/31, H Clifford Smith to Brackett that he has examined the Allan gift with Mr Arthur Stair (one of the best judges existing of English oak furniture) and suggests that 7 of 11 items be accepted as "they appear to be good and desirable examples of English oak of the 16th and 17th century and will be desirable additions to the Museum collections". |

| Historical context | These turned chairs of triangular form were also popular with furniture collectors in the nineteenth century. Two examples are visible in the photograph of Lord Llangattock asleep in the Oak Parlour of his house, The Hendre,near Monmouth, in the 1890s. This photograph, No. 2921-97, is part of the Photograph Collection. It is illustrated in The Romantic Interior by Clive Wainwright, Yale University Press, 1989, pl. 267. |

| Summary | Object Type Three-legged chairs were suitable for use on uneven floors as they would not wobble. In their simplest form turned seats were stools made by inserting three splayed legs into holes in a flat piece of wood. Materials & Making Chairs like this and other objects turned on a lathe were sometimes called 'thrown'. They were made on a pole lathe, driven by pulling on a length of cord attached to a pole. The post was attached to a spindle, which was turned by the cord. It was shaped and patterned by a gouge, or cutting tool, held against the post as it turned. Pole lathes were simple to make and could be set up anywhere. These chairs were often made from locally grown wood, in this case freshly cut oak, a tree native to Britain. The wood has since been varnished black. Time Turned armchairs and three-legged stools can be seen in medieval manuscripts, though they probably were made even earlier. Similar chairs were also made in other parts of Northern Europe and Scandinavia. They are difficult to date accurately, but in Britain many were made in the 16th and 17th centuries. We think this one dates from that time. |

| Bibliographic reference | |

| Collection | |

| Accession number | W.32-1931 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | March 27, 2003 |

| Record URL |

Download as: JSONIIIF Manifest