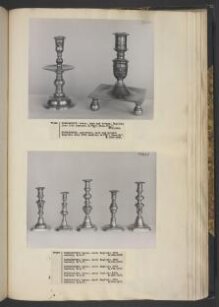

Candlestick

1820-1850 (made)

| Artist/Maker | |

| Place of origin |

Object Type

This brass candlestick is typical of the cheap domestic brass wares that were mass-produced for international markets in cities like Sheffield and Birmingham, with their strong traditions of metal production.

Function

To solve the problem of removing the stub of a used candle from the socket of a candlestick, a mechanical device was introduced in about 1730. It consisted of an iron rod fitted with circular brass discs at either end, which operated vertically within the hollow candle stem. By pushing up the button in the base, the stub was ejected at the top.

Manufacturing Process

In the 18th century and before, brass candlesticks were usually made from castings produced in a two-piece mould. The various elements, such as the base and column, were then soldered or 'brazed' together. By the early 19th century, columns were often made from extruded brass tubing. This allowed candlesticks to be made of thin gauge metal, and, as a consequence, they were much cheaper, since they required far less brass than the old cast versions.

This brass candlestick is typical of the cheap domestic brass wares that were mass-produced for international markets in cities like Sheffield and Birmingham, with their strong traditions of metal production.

Function

To solve the problem of removing the stub of a used candle from the socket of a candlestick, a mechanical device was introduced in about 1730. It consisted of an iron rod fitted with circular brass discs at either end, which operated vertically within the hollow candle stem. By pushing up the button in the base, the stub was ejected at the top.

Manufacturing Process

In the 18th century and before, brass candlesticks were usually made from castings produced in a two-piece mould. The various elements, such as the base and column, were then soldered or 'brazed' together. By the early 19th century, columns were often made from extruded brass tubing. This allowed candlesticks to be made of thin gauge metal, and, as a consequence, they were much cheaper, since they required far less brass than the old cast versions.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Brass |

| Brief description | Brass, with a raiser rod in the stem. ENGLISH; early 19th century G Russel-Davies Bequest; Brasswork |

| Dimensions |

|

| Gallery label | British Galleries:

Before the early 19th century brass candlesticks were made by casting in a two-piece mould. After that date they were often made as a single casting, or as here, from extruded brass tubing. This created a very thin-walled and cheaper product.(27/03/2003) |

| Credit line | Bequeathed by G. Russell-Davies, through the Brighton Museum |

| Object history | Probably made in Birmingham |

| Summary | Object Type This brass candlestick is typical of the cheap domestic brass wares that were mass-produced for international markets in cities like Sheffield and Birmingham, with their strong traditions of metal production. Function To solve the problem of removing the stub of a used candle from the socket of a candlestick, a mechanical device was introduced in about 1730. It consisted of an iron rod fitted with circular brass discs at either end, which operated vertically within the hollow candle stem. By pushing up the button in the base, the stub was ejected at the top. Manufacturing Process In the 18th century and before, brass candlesticks were usually made from castings produced in a two-piece mould. The various elements, such as the base and column, were then soldered or 'brazed' together. By the early 19th century, columns were often made from extruded brass tubing. This allowed candlesticks to be made of thin gauge metal, and, as a consequence, they were much cheaper, since they required far less brass than the old cast versions. |

| Collection | |

| Accession number | M.393-1917 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | March 27, 2003 |

| Record URL |

Download as: JSONIIIF Manifest