Chintz

c.1919 (made)

| Artist/Maker | |

| Place of origin |

Process samples show how objects are made by illustrating the different stages of production with unfinished examples. This group of eight process samples shows various stages in the making of chintz.

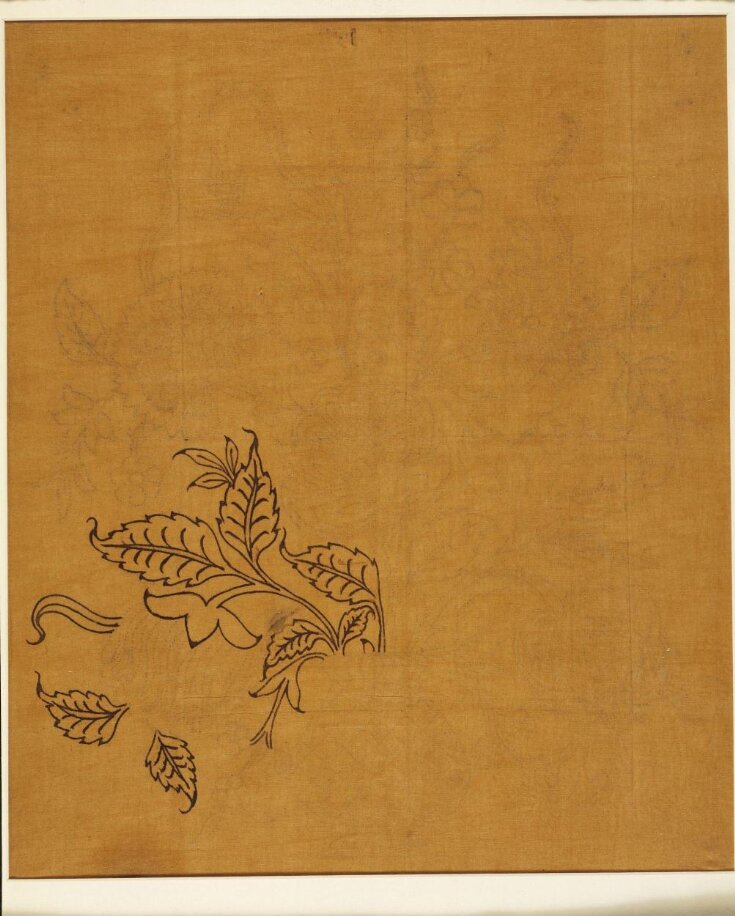

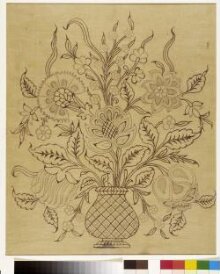

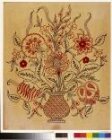

Chintz is made by a combination of mordant and resist-dyeing cotton. First the design is stenciled onto the cloth with charcoal. Then, alum and iron mordants are applied to the cloth using a kalam (a bamboo pen). Mordants are chemicals that react with dyes to change their shade and make them fast. The cotton is then submerged in a dye bath of chay root, a natural red dye from the Coromandel Coast. The chay reacts with the alum mordant to produce red, and with the iron mordant to produce black. More alum mordant is applied, and the cloth dipped in successive chay dye baths to add different shades of red to new areas. Once all the desired red shades have been acheived, the whole cloth is covered in beeswax excepting those areas that are to be dyed blue. Then the cloth is dipped into an indigo dye bath. The wax resists the dye, and protects the rest of the cloth. Once the wax has been removed, yellow dye can be applied directly over top of the blue areas to produce green.

Making chintz involves many additional stages in which the cloth is pre-treated, washed and bleached in between each colour. Chintz makers from the Coromandel Coast were particularly admired for the brilliance of their colours and the delicacy of their designs.

Chintz is made by a combination of mordant and resist-dyeing cotton. First the design is stenciled onto the cloth with charcoal. Then, alum and iron mordants are applied to the cloth using a kalam (a bamboo pen). Mordants are chemicals that react with dyes to change their shade and make them fast. The cotton is then submerged in a dye bath of chay root, a natural red dye from the Coromandel Coast. The chay reacts with the alum mordant to produce red, and with the iron mordant to produce black. More alum mordant is applied, and the cloth dipped in successive chay dye baths to add different shades of red to new areas. Once all the desired red shades have been acheived, the whole cloth is covered in beeswax excepting those areas that are to be dyed blue. Then the cloth is dipped into an indigo dye bath. The wax resists the dye, and protects the rest of the cloth. Once the wax has been removed, yellow dye can be applied directly over top of the blue areas to produce green.

Making chintz involves many additional stages in which the cloth is pre-treated, washed and bleached in between each colour. Chintz makers from the Coromandel Coast were particularly admired for the brilliance of their colours and the delicacy of their designs.

Object details

| Category | |

| Object type | |

| Parts | This object consists of 8 parts.

|

| Materials and techniques | Cotton, mordant- and resist-dyed using alum, iron, chay root, wax, indigo and possibly turmeric |

| Brief description | Eight process samples illustrating various stages in chintz production, South-east India (Coromandel Coast), c.1919 |

| Physical description | Eight cotton swatch process samples illustrating the stages of chintz production using the motif of a vase of flowers. |

| Dimensions |

|

| Credit line | Given by W.S. Hadaway, Esq. |

| Object history | Gift of Mr W.S. Hadaway of the Madras School of Art. Register entry notes Mr Hadaway's remarks: 'I am very glad if the specimens illustrating the decorating of cotton, handed over to you by Mr [G.P.] Baker are of interest. I had them prepared for Mr Baker's book on the subject [Calico painting and printing in the the East Indies in the XVIIth and XVIIIth centuries, 1921] and I believe they show in all essentials the old processes which are still in use in a few centres in India.' 7 Aug 1919. |

| Subjects depicted | |

| Summary | Process samples show how objects are made by illustrating the different stages of production with unfinished examples. This group of eight process samples shows various stages in the making of chintz. Chintz is made by a combination of mordant and resist-dyeing cotton. First the design is stenciled onto the cloth with charcoal. Then, alum and iron mordants are applied to the cloth using a kalam (a bamboo pen). Mordants are chemicals that react with dyes to change their shade and make them fast. The cotton is then submerged in a dye bath of chay root, a natural red dye from the Coromandel Coast. The chay reacts with the alum mordant to produce red, and with the iron mordant to produce black. More alum mordant is applied, and the cloth dipped in successive chay dye baths to add different shades of red to new areas. Once all the desired red shades have been acheived, the whole cloth is covered in beeswax excepting those areas that are to be dyed blue. Then the cloth is dipped into an indigo dye bath. The wax resists the dye, and protects the rest of the cloth. Once the wax has been removed, yellow dye can be applied directly over top of the blue areas to produce green. Making chintz involves many additional stages in which the cloth is pre-treated, washed and bleached in between each colour. Chintz makers from the Coromandel Coast were particularly admired for the brilliance of their colours and the delicacy of their designs. |

| Bibliographic references |

|

| Collection | |

| Accession number | T.1-1920 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | June 25, 2009 |

| Record URL |

Download as: JSONIIIF Manifest