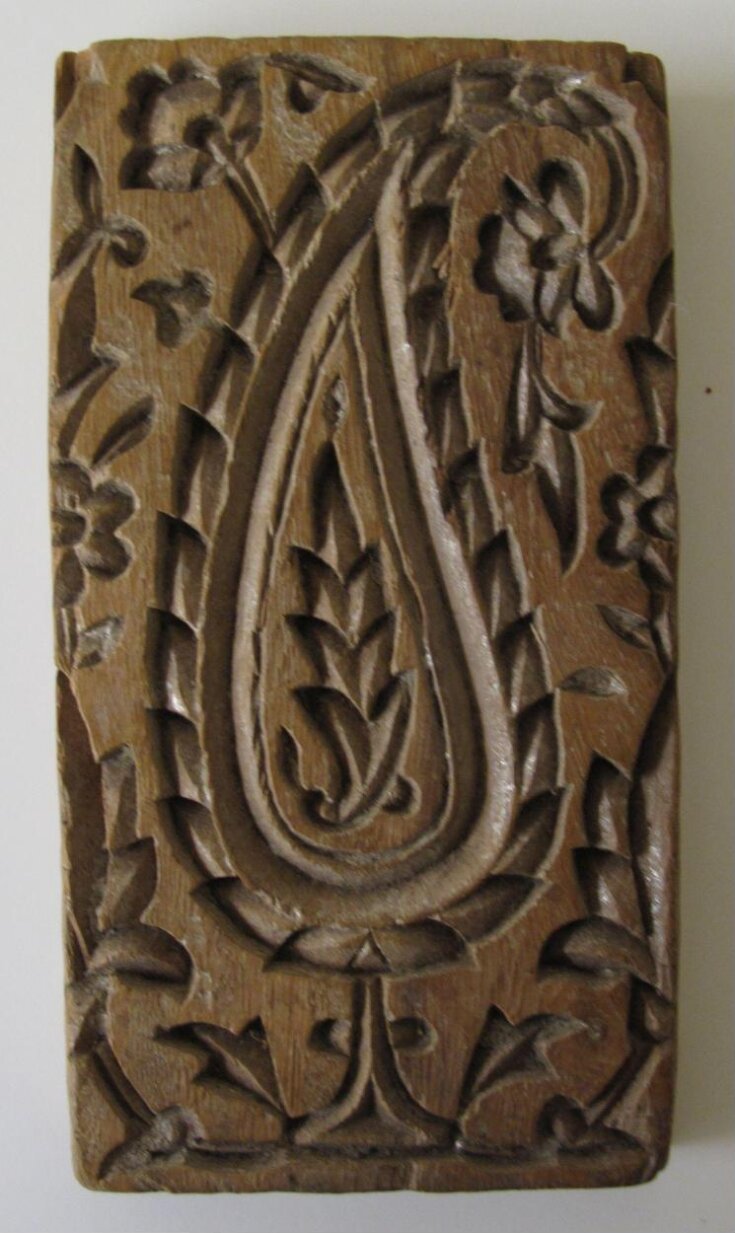

Textile Printing Block

1800-1900 (made)

| Place of origin |

This square wooden panel was most likely used as a printing block for fabrics and textiles. A solid block of colour would have been applied to the block, which was then pressed onto the fabric, imprinting it with the carved motif. According to Murdoch Smith (the Director of the Persian Telegraph Department, a British officer in the Royal Engineers), speaking in 1876 in Iran, the art of carving woodblocks was confined almost exclusively to Abadeh, a large village in the centre of Persia. The pattern would have been printed onto the fabric with a series of woodblocks made from pearwood and carved in relief, each colour requiring a different block.

It was recognised that considerable skill was needed for cutting the blocks and for preparing the dyestuffs, but a good eye and an even hand were also required from the printer.

The black outlines which form the basis of the designs were printed first and then other colours were printed, one by one, onto the relevant areas. Usually, parts of the design were left white. A limited number of colours were used: black, red, blue and yellow, which could, by overprinting or varying the intensity, produce purple, brown and green. The colours were obtained from natural sources to which a thickening agent – a gum, oil or starch – needed to be added together with a mordant (usually alum) which would act as an agent and bind the dye to the fabric.

During the second half of the nineteenth century, the growing strength of European textile production dramatically impacted the Iranian textile industry; however, printed cottons continued to be made in Iran, as many were exported to Georgia due to the Russian prohibition of British imports. This Iranian export trade continued for many years and a British Government Report dated 1873 stated “…the textile fabrics produced in Persia continued to find a ready sale in Turkey, Georgia and the south of Russia, generally…in Azerbaijan there are no manufactures of cloth, but a large trade is carried on with Georgia in printed cottons, which are imported plain from Manchester, and receive coloured patterns in Tabreez [Tabriz]”.

It was recognised that considerable skill was needed for cutting the blocks and for preparing the dyestuffs, but a good eye and an even hand were also required from the printer.

The black outlines which form the basis of the designs were printed first and then other colours were printed, one by one, onto the relevant areas. Usually, parts of the design were left white. A limited number of colours were used: black, red, blue and yellow, which could, by overprinting or varying the intensity, produce purple, brown and green. The colours were obtained from natural sources to which a thickening agent – a gum, oil or starch – needed to be added together with a mordant (usually alum) which would act as an agent and bind the dye to the fabric.

During the second half of the nineteenth century, the growing strength of European textile production dramatically impacted the Iranian textile industry; however, printed cottons continued to be made in Iran, as many were exported to Georgia due to the Russian prohibition of British imports. This Iranian export trade continued for many years and a British Government Report dated 1873 stated “…the textile fabrics produced in Persia continued to find a ready sale in Turkey, Georgia and the south of Russia, generally…in Azerbaijan there are no manufactures of cloth, but a large trade is carried on with Georgia in printed cottons, which are imported plain from Manchester, and receive coloured patterns in Tabreez [Tabriz]”.

Object details

| Categories | |

| Object type | |

| Materials and techniques | Carved pearwood |

| Brief description | Wooden block carved from pearwood, Iran, Qajar period, 1800-1900 |

| Physical description | Square shaped wooden panel carved with a single floral spray (paisley) stemming from a spray. The relief decoration has stained a darker grey with use. |

| Dimensions |

|

| Object history | The object was bequeathed to the Museum by Robert Taylor. |

| Summary | This square wooden panel was most likely used as a printing block for fabrics and textiles. A solid block of colour would have been applied to the block, which was then pressed onto the fabric, imprinting it with the carved motif. According to Murdoch Smith (the Director of the Persian Telegraph Department, a British officer in the Royal Engineers), speaking in 1876 in Iran, the art of carving woodblocks was confined almost exclusively to Abadeh, a large village in the centre of Persia. The pattern would have been printed onto the fabric with a series of woodblocks made from pearwood and carved in relief, each colour requiring a different block. It was recognised that considerable skill was needed for cutting the blocks and for preparing the dyestuffs, but a good eye and an even hand were also required from the printer. The black outlines which form the basis of the designs were printed first and then other colours were printed, one by one, onto the relevant areas. Usually, parts of the design were left white. A limited number of colours were used: black, red, blue and yellow, which could, by overprinting or varying the intensity, produce purple, brown and green. The colours were obtained from natural sources to which a thickening agent – a gum, oil or starch – needed to be added together with a mordant (usually alum) which would act as an agent and bind the dye to the fabric. During the second half of the nineteenth century, the growing strength of European textile production dramatically impacted the Iranian textile industry; however, printed cottons continued to be made in Iran, as many were exported to Georgia due to the Russian prohibition of British imports. This Iranian export trade continued for many years and a British Government Report dated 1873 stated “…the textile fabrics produced in Persia continued to find a ready sale in Turkey, Georgia and the south of Russia, generally…in Azerbaijan there are no manufactures of cloth, but a large trade is carried on with Georgia in printed cottons, which are imported plain from Manchester, and receive coloured patterns in Tabreez [Tabriz]”. |

| Bibliographic references |

|

| Collection | |

| Accession number | W.41-1930 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | June 24, 2009 |

| Record URL |

Download as: JSONIIIF Manifest