Inkstand

ca. 1780 (made)

| Artist/Maker | |

| Place of origin |

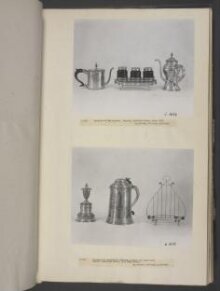

This inkstand would have been used on a desk or dressing table and contains an inkwell and pounce pots (pots with fine powder used for drying the ink). The pots are made of blue glass, fashionable in the late eighteenth century and are mounted on a frame of Sheffield Plate. Invented in Sheffield in the 1740s, Sheffield Plate involved joining by heat a thin layer of silver to a block of copper. The block was rolled into sheet and worked as one metal.

Sheffield plate had great commercial advantages over earlier attempts to imitate silver. It was easier and cheaper to make and gave the consumer the appearance of silver without the expense. Machines such as the fly press for pierced work on baskets, cruets, inkstands and salts, and steel dies to stamp designs on sheets of Sheffield plate or silver sped up production and opened up silver-style goods to a broader market.

Sheffield plate had great commercial advantages over earlier attempts to imitate silver. It was easier and cheaper to make and gave the consumer the appearance of silver without the expense. Machines such as the fly press for pierced work on baskets, cruets, inkstands and salts, and steel dies to stamp designs on sheets of Sheffield plate or silver sped up production and opened up silver-style goods to a broader market.

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 7 parts.

|

| Materials and techniques | Sheffield Plate |

| Brief description | Sheffield plate with blue glass bottles, Sheffield or Birmingham, ca.1780 |

| Physical description | Sheffield Plate inkstand with plain parallel sided tray and cusped arch ends, with a pierced arcade border and beaded rim, with three circular pierced ring supports for an inkwell and pounce pots, the tray on four ball an dclaw feet, the inkpots of blue glass with pierced and beaded lids. |

| Dimensions |

|

| Styles | |

| Historical context | Invented in Sheffield in the 1740s, Sheffield Plate involved joining by heat a thin layer of silver to a block of copper. The block was rolled into sheet and worked as one metal. The industry this material created flourished for about 100 years until superseded by electroplating in the 1840s. Sheffield plate had great commercial advantages over earlier attempts to imitate silver: French plating, close plating and silvering. It was easier and cheaper to make and gave the consumer the appearance of silver without the expense. There was no social stigma attached to buying Sheffield plate rather than silver, but its durability was questioned. In 1774 Horace Walpole wrote critically to Horace Mann, "Birmingham covers for dishes ... All plated silver wears abominably and turns to brass like the age. You would not bear it six months." To which Mann replied, "I am sorry to see you disapprove of the double plate covers for dishes. I was persuaded to get them by those who assured me they could not be distinguished and for such use would be as lasting as silver." By 1800, factories operated in Sheffield, Birmingham, London, Paris and St. Petersburg. Powerful machinery made the process more efficient. Improved flatting mills rolled the plated copper into thinner, cheaper sheets. Advances in the steel industry provided better equipment for stamping out decorative patterns. Dishes and tureens were produced in great quantities at a fraction of their cost in silver. Traditionally, metal goods were produced in a network of small, complementary workshops. An object might pass through several of these before it was finished. From the mid-eighteenth century this changed, as entrepreneurs created large factories where all the skills could be contained under one roof. Matthew Boulton (1728-1809) claimed that his Soho factory in Birmingham had: `seven or eight hundred persons employ'd in almost all those Arts that are applicable to the manufacturing of all the metals... I have almost every machine that is applicable to those Arts. I have two Water mills employed in rolling, polishing, grinding and turning various sorts of laths.' (letter to James Adam 1 Oct. 1770) These new manufactories which grew up outside London, in Birmingham and Sheffield exploited new technology to create cheaper products. A significant technical innovation for the 18th-century metalworker, pre-dating Sheffield plate, was the rolling or flatting mill. By producing uniform sheet metal, these mills eliminated the need to raise silver by hand. The result was thinner gauge, cheaper silver. Manufacturers not only employed this technology but developed a number of highly successful new techniques for making and decorating Sheffield plate, some of which spread to silversmithing. Machines such as the fly press for pierced work on baskets, cruets, inkstands and salts, and steel dies to stamp designs on sheets of Sheffield plate or silver sped up production and opened up silver-style goods to a broader market. |

| Production | Probably Sheffield or Birmingham |

| Summary | This inkstand would have been used on a desk or dressing table and contains an inkwell and pounce pots (pots with fine powder used for drying the ink). The pots are made of blue glass, fashionable in the late eighteenth century and are mounted on a frame of Sheffield Plate. Invented in Sheffield in the 1740s, Sheffield Plate involved joining by heat a thin layer of silver to a block of copper. The block was rolled into sheet and worked as one metal. Sheffield plate had great commercial advantages over earlier attempts to imitate silver. It was easier and cheaper to make and gave the consumer the appearance of silver without the expense. Machines such as the fly press for pierced work on baskets, cruets, inkstands and salts, and steel dies to stamp designs on sheets of Sheffield plate or silver sped up production and opened up silver-style goods to a broader market. |

| Bibliographic reference | Angus Patterson, "A Timely Acquisition: The V&A's Matthew Boulton Pattern Book, ca. 1779", Journal of the Antique Metalware Society, Vol. 17, June 2009, pp. 58-75, p. 65 ill. |

| Collection | |

| Accession number | M.267-1920 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | March 23, 2009 |

| Record URL |

Download as: JSONIIIF Manifest