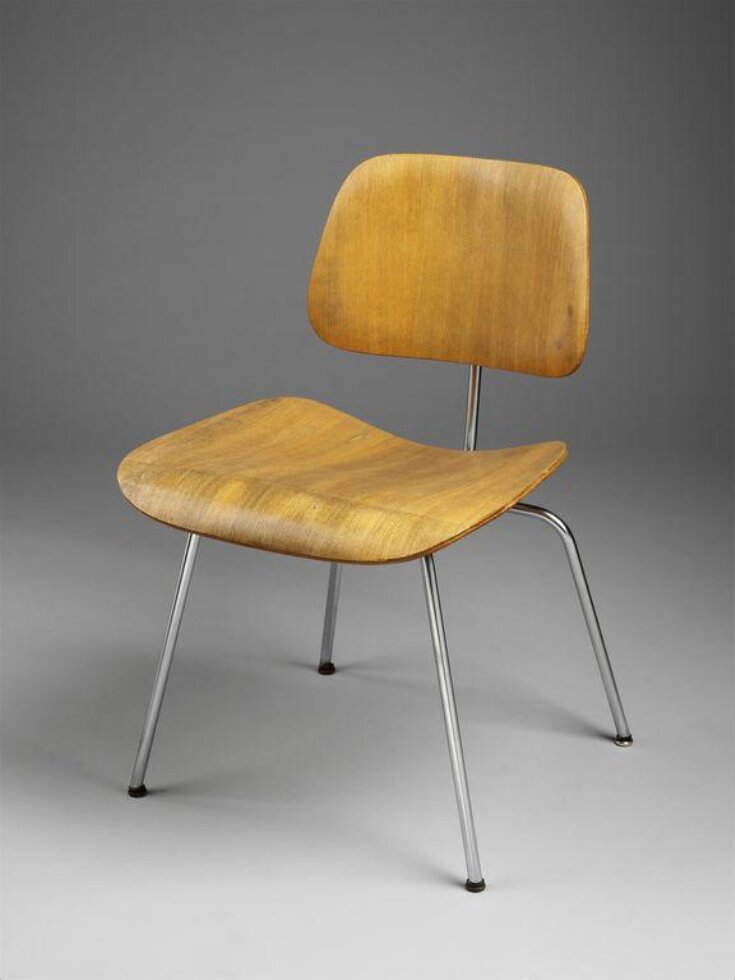

DCM (dining chair metal)

Chair

ca. 1947 (made), 1945 (designed)

ca. 1947 (made), 1945 (designed)

| Artist/Maker | |

| Place of origin |

Charles Eames (1907–78) and Ray Kaiser Eames (1912–88) were among the most influential designers of the 20th century. Working across a huge range of fields, from furniture to sculpture, film, photography, architecture and product design, their impact on the shape of postwar (and Cold War ) US culture was huge and has lead the Library of Congress to describe the designers as having ‘[given] shape to America's twentieth century’.

The Eameses are perhaps best known for their work as furniture designers. The DCM, designed in 1945, is one of their most significant and influential chairs. It striking form, with moulded plywood seat and back supported on a tubular steel frame, had a giant impact on 1940s and 1950s furniture design around the world. Within a decade of the DCM’s design, in virtually every European country, in the US and in Japan, plywood had started to be used both in direct imitation of the Eames chair and, influenced by the Eames’ furniture, as the material for the most up-to-date design. It is not hyperbole to claim that the DCM became the most imitated chair of the mid-twentieth century; not only did Eames-influenced furniture appear in high-style or design-conscious interiors, it was also instrumental in plywood becoming a staple of mass-market commercial and institutional furniture.

The Eameses are perhaps best known for their work as furniture designers. The DCM, designed in 1945, is one of their most significant and influential chairs. It striking form, with moulded plywood seat and back supported on a tubular steel frame, had a giant impact on 1940s and 1950s furniture design around the world. Within a decade of the DCM’s design, in virtually every European country, in the US and in Japan, plywood had started to be used both in direct imitation of the Eames chair and, influenced by the Eames’ furniture, as the material for the most up-to-date design. It is not hyperbole to claim that the DCM became the most imitated chair of the mid-twentieth century; not only did Eames-influenced furniture appear in high-style or design-conscious interiors, it was also instrumental in plywood becoming a staple of mass-market commercial and institutional furniture.

Object details

| Category | |

| Object type | |

| Title | DCM (dining chair metal) (assigned by artist) |

| Materials and techniques | Moulded birch plywood seat and back with tubular steel frame and rubber mounts |

| Brief description | DCM (dining chair metal), designed by Charles and Ray Eames, manufactured by the Evans Products Company for the Herman Miller furniture company, moulded birch plywood seat and back with tubular steel frame and rubber mounts, Los Angeles, designed 1945, manufactured about 1947 |

| Physical description | Chair with seat and back of moulded birch plywood and a slender tubular steel frame and legs. The seat and back are organically shaped and moulded to fit the human body. They are attached to the frame by rubber 'shock' mounts - pieces of rubber that are glued to the underside of the seat and back that the frame can be screwed into. There are two rubber mounts on the back of the seat and three on the underside of the chair. The frame and legs are made of three pieces of bent tubular steel - one forming the support for the back and seat and the other two forming the seat. The seat and back support is welded to the legs. The legs are rounded and flattened at the ends to form feet with small pieces of rubber around the top. |

| Dimensions |

|

| Marks and inscriptions | 'herman miller / EVANS / Charles Eames' (Printed paper label adhered to underside of chair) |

| Gallery label | Text from Plywood: Material of the Modern World (15 July-12 November 2017)

DCM (DINING CHAIR METAL)

Designed 1945

The three-dimensional curve of this chair’s

seat was influenced by the Eames’s wartime

work moulding complex plywood shapes.

The DCM (dining chair metal) was the most

imitated chair of the post-war era. Eamesinfluenced

furniture appeared around the

world in both fashionable interiors and on

the mass market. In the early 1950s exact

copies of their chairs were already being

sold as far away as Japan.

Designed by Charles (1907–78) and

Ray Eames (1912–88)

Manufactured about 1947 by the Evans Products Company

Los Angeles, USA

Moulded 5-ply birch plywood seat and back

with tubular steel frame and rubber mounts

V&A: W.7-2017(2017) |

| Object history | There is in V&A's collection a prototype of the DCM, with only three legs, which never went into production (W.10-1982). This chair is a very early example of the production model. It was made in around 1947 by the Evans Plywood Company. DCMs were later manufactured on a much larger scale by both Evans and Herman Miller. The chair was made using techniques that were dropped in the large-scale production and as such, demonstrates the process by which the design was developed for mass manufacture. Charles and Ray Eames had initially intended for the DCM to have what they termed an ‘integral’ finish, meaning that it would not have any added finish or varnish. This was the approach that they had used on the 1942 leg splint. Although the designers agreed to the addition of a varnish on later Evans and Herman Miller chairs this example, very unsually, retains the original (unvarnished) finish. The construction of the frame is also different from that seen on later models. Each of the three connection points in the frame was done by hand, with the frame maker cutting into each rod, inserting the connecting rod into this gap, and then adding solder. After the frame had been joined, the frame maker used a grinder to remove excess solder (some remnants of solder not removed through this process remain visible). The Eames’ wanted a more straightforward and stronger connection than that achieved on this early type of frame, and most of the Evans production and Herman Miller chairs have frames that were joined electrostatically, with no cutting into the steel rods. In its unusual construction, this chair shows the design of the DCM frame at a very early point in its development and production. The chair has on the underside of its seat a paper label which includes both the Herman Miller and Evans logos (Herman Miller on the left, Evans in the centre). Herman Miller signed a contract to distribute Evans-manufactured DCM chairs in late 1946. |

| Historical context | Charles Eames first began working with moulded plywood furniture in 1941 when he designed, with Eero Saarinen, an ambitious, three-dimensionally moulded plywood chair and armchair. These designs won first prize in the ‘Organic Design in Home Furnishings’ competition at New York’s Museum of Modern Art (MoMA). The armchair, with a complex plywood seat that the designers referred to as a ‘wood shell’, was an attempt to form a fully supportive shape for the sitter that would provide a lightweight upholstered chair carried on thin legs (20 lbs/9.07 kg compared to 45 lbs/20.4 kg for a traditional upholstered armchair). To manufacture the shells, the designers were paired with the very experienced Haskelite Corporation, one of nine manufacturers that had agreed to help bring to market the competition winners. When it came to making the chairs, the Haskelite company was challenged by the need to achieve such a complex-curved shape in a size much smaller than that of the aircraft work that formed its usual production. Only a small number of the chairs were completed and offered for sale before the US entry into the war in the same year (1941). Before the end of the MoMA project (June 1941) Charles Eames and Ray Kaiser married and moved to Los Angeles, where, during the war years, they continued the attempt to mould plywood furniture suitable for mass production. They built their own very small bag moulding device, initially in their flat. This clearly drew on Charles’s experience of working with Haskelite (including visits to its headquarters in Grand Rapids, Michigan), on his direct experience of working in factories and on building sites, and on the fact that the technology was widely used by a number of Los Angeles-based aircraft companies. While the Eames’ mould was simpler than any commercial process (it employed a bicycle pump for pressurization), the principles were identical. The first result was a single-piece, three-dimensionally moulded seat and back, similar to the MoMA armless chair but with a slit in the back to allow for simpler moulding. Although wartime restrictions prevented the commercial development of the chair the couple worked on similar seat designs for military aircraft. This demonstrated their ongoing commitment to moulded plywood products, as did the remarkable free-form plywood sculptures made by Ray. The first moulded plywood object to which the Eameses were able to devote themselves full time, and which they were able to see through to genuine mass production, was an unlikely commission for the US Navy: a plywood leg splint for injured sailors. The design and method of manufacture of the splint, initially on a small scale (in 1942–43) and then in quantities of up to 150,000 (1943–45), enabled the most important period of sustained work on plywood in the Eames’ careers to date. The taking over of their production by a major wood products manufacturer in 1943 resulted in their considerable investment in tooling and provision of a larger splint factory. The expansion of the Eameses’ small practice into, first, a small factory and then to a larger one enabled them to take on contracts for plywood aircraft parts for different companies, although they were not pioneers in this production, a fact made clear when the sculpture and splints were exhibited at MoMA in 1944, in the wider context of wartime plywood moulding. But the experience gained over these few years, from their designs and art, and their venture into manufacturing (including the constraints of military contracts), meant that the Eameses’ knowledge of plywood moulding had expanded very fast. Although such work had begun (in the work with Saarinen) on single-shell forms, by 1945 they had dismantled that form in favour of entirely separate seats and backs connected with either wood or metal frame elements. These seats and backs were moulded in three dimensions but the abandonment of the shell form greatly simplified the technical challenges related to moulding. The DCM was the chair that resulted from these experiments. It was a remarkable design, not least owing to the relationship between the very thin, almost spindly, metal frame and the biomorphic wooden seat and back, each of which seemed to float off the frame. This was achieved by joining wood and metal to rubber mounts using screws and glue. But instead of the modernist imagery of machine production alone, the Eameses’ chair was a zoomorphic form, suggestive of a creature with four legs, a pelvis and a head. This impression led the contemporary but more traditional furniture designer Edward Wormley to poke fun at the chair’s silhouette as having led within just a few years to ‘a mass of mosquitoes posing as tables, chairs and carts’. |

| Summary | Charles Eames (1907–78) and Ray Kaiser Eames (1912–88) were among the most influential designers of the 20th century. Working across a huge range of fields, from furniture to sculpture, film, photography, architecture and product design, their impact on the shape of postwar (and Cold War ) US culture was huge and has lead the Library of Congress to describe the designers as having ‘[given] shape to America's twentieth century’. The Eameses are perhaps best known for their work as furniture designers. The DCM, designed in 1945, is one of their most significant and influential chairs. It striking form, with moulded plywood seat and back supported on a tubular steel frame, had a giant impact on 1940s and 1950s furniture design around the world. Within a decade of the DCM’s design, in virtually every European country, in the US and in Japan, plywood had started to be used both in direct imitation of the Eames chair and, influenced by the Eames’ furniture, as the material for the most up-to-date design. It is not hyperbole to claim that the DCM became the most imitated chair of the mid-twentieth century; not only did Eames-influenced furniture appear in high-style or design-conscious interiors, it was also instrumental in plywood becoming a staple of mass-market commercial and institutional furniture. |

| Bibliographic reference | Wilk, Christopher. Plywood: A Material Story. London: Thames & Hudson / V&A, 2017

|

| Collection | |

| Accession number | W.7-2017 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | October 26, 2016 |

| Record URL |

Download as: JSON