The Liberator

Handgun

August 2013 (manufactured)

August 2013 (manufactured)

| Artist/Maker | |

| Place of origin |

Texan law student Cody Wilson founded Defense Distributed to ‘defend the civil liberty of popular access to arms as guaranteed by the United States Constitution’. He created designs for guns and gun components that can be downloaded by anyone anywhere in the world and printed out on a 3D printer.

Wilson fired the world’s first 3D-printed gun, The Liberator, on 6 May 2013. The invention of this so-called wiki weapon sparked intense debate. It transforms the way we think about new manufacturing technologies and the unregulated sharing of designs online.

Design drawings for the handgun were downloaded over 100,000 times after they were released online on the day of firing. The files were seized by the US government a few days later and Wilson was ordered to remove them from his website. Wilson says of his work that he ‘never thought of it in terms of design’. The design and distribution of The Liberator is for him a political act.

The Liberator gun parts in nylon and plaster were printed by Digits2Widgets in London in September 2013 from the STL (stereo lithography) files released by Wilson. The need to print in London came about because The Liberator weapon and parts acquired by the museum directly from Wilson are yet to arrive at the V&A due to multiple delays caused by obtaining relevant export licenses.

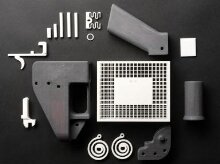

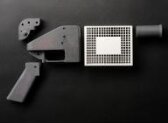

The Digits2Widgets gun parts are an important acquisition in their own right because they tell a story of the awkward, semi-regulated space in the law that the 3D-printed weapon represents. To ensure that Digits2Widgets were not manufacturing a workable handgun (the company do not have a licence to manufacture handguns) the frame, grip, barrel and hammer body were 3D printed in plaster. The springs, trigger spring, frame pins, trigger, hammer, hammer pin, grip pin and a washer are made from ABS plastic. Further to this, the dimensions of the Liberator gun parts made in plaster were also modified by a millimetre to ensure the pieces would not fit together.

Wilson fired the world’s first 3D-printed gun, The Liberator, on 6 May 2013. The invention of this so-called wiki weapon sparked intense debate. It transforms the way we think about new manufacturing technologies and the unregulated sharing of designs online.

Design drawings for the handgun were downloaded over 100,000 times after they were released online on the day of firing. The files were seized by the US government a few days later and Wilson was ordered to remove them from his website. Wilson says of his work that he ‘never thought of it in terms of design’. The design and distribution of The Liberator is for him a political act.

The Liberator gun parts in nylon and plaster were printed by Digits2Widgets in London in September 2013 from the STL (stereo lithography) files released by Wilson. The need to print in London came about because The Liberator weapon and parts acquired by the museum directly from Wilson are yet to arrive at the V&A due to multiple delays caused by obtaining relevant export licenses.

The Digits2Widgets gun parts are an important acquisition in their own right because they tell a story of the awkward, semi-regulated space in the law that the 3D-printed weapon represents. To ensure that Digits2Widgets were not manufacturing a workable handgun (the company do not have a licence to manufacture handguns) the frame, grip, barrel and hammer body were 3D printed in plaster. The springs, trigger spring, frame pins, trigger, hammer, hammer pin, grip pin and a washer are made from ABS plastic. Further to this, the dimensions of the Liberator gun parts made in plaster were also modified by a millimetre to ensure the pieces would not fit together.

Delve deeper

Discover more about this object

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 16 parts. (Some alternative part names are also shown below)

|

| Title | The Liberator (assigned by artist) |

| Materials and techniques | 3D printed in plaster and plastic |

| Brief description | 3D printed hand gun, in plaster and plastic, printed by Digits 2 Widgets, manufactured from the CAD designed by Defense Distributed, 2013. |

| Physical description | 3D printed hand gun, frame, barrel, grip and hammer body in grey, springs, trigger, trigger springs, washer, frame pins, hammer pins, base section and cage section in white. |

| Dimensions |

|

| Gallery label |

|

| Credit line | Purchased by the Design Fund |

| Summary | Texan law student Cody Wilson founded Defense Distributed to ‘defend the civil liberty of popular access to arms as guaranteed by the United States Constitution’. He created designs for guns and gun components that can be downloaded by anyone anywhere in the world and printed out on a 3D printer. Wilson fired the world’s first 3D-printed gun, The Liberator, on 6 May 2013. The invention of this so-called wiki weapon sparked intense debate. It transforms the way we think about new manufacturing technologies and the unregulated sharing of designs online. Design drawings for the handgun were downloaded over 100,000 times after they were released online on the day of firing. The files were seized by the US government a few days later and Wilson was ordered to remove them from his website. Wilson says of his work that he ‘never thought of it in terms of design’. The design and distribution of The Liberator is for him a political act. The Liberator gun parts in nylon and plaster were printed by Digits2Widgets in London in September 2013 from the STL (stereo lithography) files released by Wilson. The need to print in London came about because The Liberator weapon and parts acquired by the museum directly from Wilson are yet to arrive at the V&A due to multiple delays caused by obtaining relevant export licenses. The Digits2Widgets gun parts are an important acquisition in their own right because they tell a story of the awkward, semi-regulated space in the law that the 3D-printed weapon represents. To ensure that Digits2Widgets were not manufacturing a workable handgun (the company do not have a licence to manufacture handguns) the frame, grip, barrel and hammer body were 3D printed in plaster. The springs, trigger spring, frame pins, trigger, hammer, hammer pin, grip pin and a washer are made from ABS plastic. Further to this, the dimensions of the Liberator gun parts made in plaster were also modified by a millimetre to ensure the pieces would not fit together. |

| Collection | |

| Accession number | CD.1:1 to 16-2013 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | January 17, 2014 |

| Record URL |

Download as: JSON