Katy Perry Lashes

False Eyelashes

2013 (manufactured)

2013 (manufactured)

| Artist/Maker | |

| Place of origin |

These eyelashes are available in any high street pharmacy, part of an industry worth £110 million per year in the UK. They are also a key part of the aesthetic of the pop star Katy Perry, whose image as a bright-eyed girl-next-door has led to endorsements for many beauty products.

The lashes are made by hand-sewing individual hairs on to a piece of string. The job requires considerable skill and excellent eyesight. They are then sent to a factory to be cut into a range of styles.

In 2013, an article in the Sun on Sunday revealed that women in Asia were being paid between 1p and 8p per pair for making lashes that cost around £6 on the British high street. The lashes are a part of street fashion today, but also show how globalised manufacturing can connect one of the most famous women in the world with women living on the poverty line in South-East Asia.

As an artefact of global consumer culture, the false eyelashes are compelling, and Eylure’s history also tells the story of how globalisation has changed manufacturing. The brand was originally a British company and the first manufacturer of false eyelashes in the world. The company was started by the makeup artist brothers Eric and David Aylott in the 1940s, and began using pieceworkers and a small manufacturing facility in Welwyn Garden City.

Eylure grew through the 40s, 50s and 60s. In the late 1960s the company expanded its manufacturing to a facility in Cwmbran, Wales. The hair used for the lashes was imported in two shades: lighter colours imported from mainland Europe and black from China and later India. A single ounce of hair could produce 2000 lashes. The lashes sold in the 1960s for £5 per pair, the equivalent to around £100 today.

The Eylure brand has changed hands several times and is now owned by Original Additions. Eylure subcontract the manufacture of the lashes to PT Korindah in Indonesia, a firm that also make lashes for L’Oreal, Shu Uemura and other brands.

The lashes are made by hand-sewing individual hairs on to a piece of string. The job requires considerable skill and excellent eyesight. They are then sent to a factory to be cut into a range of styles.

In 2013, an article in the Sun on Sunday revealed that women in Asia were being paid between 1p and 8p per pair for making lashes that cost around £6 on the British high street. The lashes are a part of street fashion today, but also show how globalised manufacturing can connect one of the most famous women in the world with women living on the poverty line in South-East Asia.

As an artefact of global consumer culture, the false eyelashes are compelling, and Eylure’s history also tells the story of how globalisation has changed manufacturing. The brand was originally a British company and the first manufacturer of false eyelashes in the world. The company was started by the makeup artist brothers Eric and David Aylott in the 1940s, and began using pieceworkers and a small manufacturing facility in Welwyn Garden City.

Eylure grew through the 40s, 50s and 60s. In the late 1960s the company expanded its manufacturing to a facility in Cwmbran, Wales. The hair used for the lashes was imported in two shades: lighter colours imported from mainland Europe and black from China and later India. A single ounce of hair could produce 2000 lashes. The lashes sold in the 1960s for £5 per pair, the equivalent to around £100 today.

The Eylure brand has changed hands several times and is now owned by Original Additions. Eylure subcontract the manufacture of the lashes to PT Korindah in Indonesia, a firm that also make lashes for L’Oreal, Shu Uemura and other brands.

Object details

| Categories | |

| Object type | |

| Parts | This object consists of 5 parts.

|

| Title | Katy Perry Lashes (manufacturer's title) |

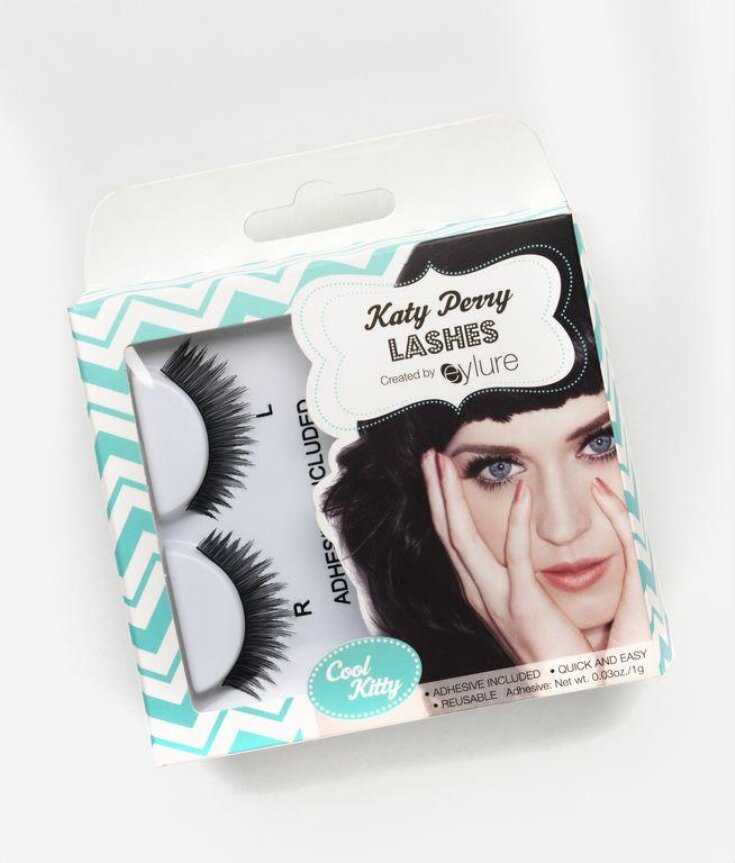

| Materials and techniques | Vacuum-formed plastic, printed ink and hand-knitted eyelashes of human hair. |

| Brief description | Katy Perry false eyelashes, manufactured in Indonesia for Eyelure, 2013. |

| Physical description | Printed cardboard box with cellophane window, featuring an image of pop singer Katy Perry, white vacuum-formed plastic tray, printed with logo and false eyelashes of human hair. |

| Dimensions |

|

| Production type | Mass produced |

| Gallery label |

|

| Credit line | Given by Gethin Chamberlain |

| Summary | These eyelashes are available in any high street pharmacy, part of an industry worth £110 million per year in the UK. They are also a key part of the aesthetic of the pop star Katy Perry, whose image as a bright-eyed girl-next-door has led to endorsements for many beauty products. The lashes are made by hand-sewing individual hairs on to a piece of string. The job requires considerable skill and excellent eyesight. They are then sent to a factory to be cut into a range of styles. In 2013, an article in the Sun on Sunday revealed that women in Asia were being paid between 1p and 8p per pair for making lashes that cost around £6 on the British high street. The lashes are a part of street fashion today, but also show how globalised manufacturing can connect one of the most famous women in the world with women living on the poverty line in South-East Asia. As an artefact of global consumer culture, the false eyelashes are compelling, and Eylure’s history also tells the story of how globalisation has changed manufacturing. The brand was originally a British company and the first manufacturer of false eyelashes in the world. The company was started by the makeup artist brothers Eric and David Aylott in the 1940s, and began using pieceworkers and a small manufacturing facility in Welwyn Garden City. Eylure grew through the 40s, 50s and 60s. In the late 1960s the company expanded its manufacturing to a facility in Cwmbran, Wales. The hair used for the lashes was imported in two shades: lighter colours imported from mainland Europe and black from China and later India. A single ounce of hair could produce 2000 lashes. The lashes sold in the 1960s for £5 per pair, the equivalent to around £100 today. The Eylure brand has changed hands several times and is now owned by Original Additions. Eylure subcontract the manufacture of the lashes to PT Korindah in Indonesia, a firm that also make lashes for L’Oreal, Shu Uemura and other brands. |

| Collection | |

| Accession number | CD.24:1 to 5-2014 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | January 16, 2014 |

| Record URL |

Download as: JSON