Chandelier

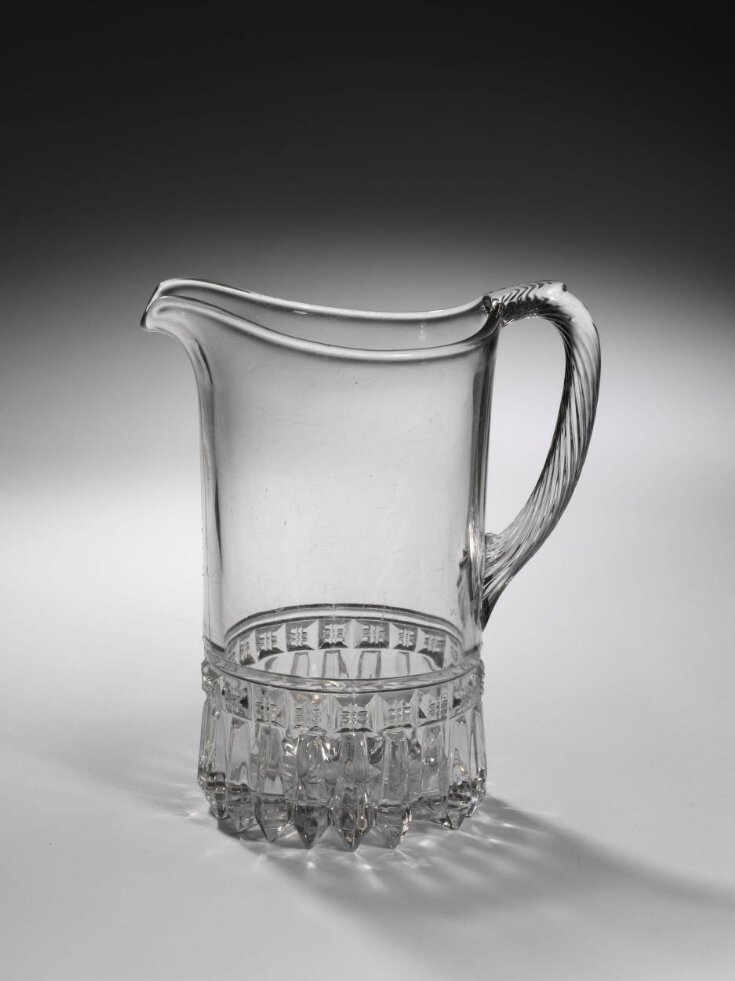

Jug

ca. 1890 (made)

ca. 1890 (made)

| Artist/Maker | |

| Place of origin |

American pressed glass became a widely used popular household product and the manufacture process meant that it could be sold at a more affordable price than hand blown or cut glass. The technique of press-moulding glass with the aid of a hand-operated machine was first perfected in the United States of America in the early 1820s. It took only two people to shape a measured quantity of hot glass in a heated metal mould. By simply depressing a lever, a metal plunger was lowered into the glass, forcing it into the patterned mould. By the 1830s this method had spread to Europe and Britain, giving rise to stylistic changes and revolutionising the availability of glassware. The technique made the mid- to late 19th century the first period of true mass production. In the 1890s the introduction of steam- powered presses improved quality while cutting costs even further.

The American glass producers' inventiveness met the need for decorative yet practical objects for the home. A wide variety of patterns were developed simulating those on finest cut glass.

The American glass producers' inventiveness met the need for decorative yet practical objects for the home. A wide variety of patterns were developed simulating those on finest cut glass.

Object details

| Categories | |

| Object type | |

| Title | Chandelier (popular title) |

| Materials and techniques | Press-moulded glass |

| Brief description | Jug, press-moulded glass with 'Chandelier' pattern, manufactured by O'Hara Glass, Pittsburgh, ca. 1890 |

| Physical description | Jug, of press-moulded glass with heavy moulded base imitating cut glass chandelier pendents. |

| Dimensions |

|

| Production type | Mass produced |

| Credit line | Given by Mr Louis and Mrs Linda Tanner |

| Summary | American pressed glass became a widely used popular household product and the manufacture process meant that it could be sold at a more affordable price than hand blown or cut glass. The technique of press-moulding glass with the aid of a hand-operated machine was first perfected in the United States of America in the early 1820s. It took only two people to shape a measured quantity of hot glass in a heated metal mould. By simply depressing a lever, a metal plunger was lowered into the glass, forcing it into the patterned mould. By the 1830s this method had spread to Europe and Britain, giving rise to stylistic changes and revolutionising the availability of glassware. The technique made the mid- to late 19th century the first period of true mass production. In the 1890s the introduction of steam- powered presses improved quality while cutting costs even further. The American glass producers' inventiveness met the need for decorative yet practical objects for the home. A wide variety of patterns were developed simulating those on finest cut glass. |

| Bibliographic references |

|

| Collection | |

| Accession number | C.27-2012 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | September 11, 2012 |

| Record URL |

Download as: JSONIIIF Manifest