Chair

ca. 1725-1740 (made)

| Artist/Maker | |

| Place of origin |

Rush seats were common in the 18th and 19th centuries, even for fashionable chairs such as this. Rush was a cheap but visually appealing and comfortable material for a seat. Itinerant rush-makers replaced rush seats when they wore out, but following the decline in this craft, many chairs which were originally rushed have had their rush replaced with upholstery. Rushes grow widely, along river banks and in coastal areas, and were used for basket-making and floor matting as well as seating. For this reason rush chair seat seats were often described as 'matted'. For making chair seats, the long, tough fibres were wetted, then twisted and knotted together to form cords long enough to wrap around the seat frame. Some chairs, such as this example, had a removable seat frame, making re-rushing relatively easy. Rush seats are prone to wear and breakage, so the rush on 18th-century chairs will almost certainly be a later replacement.

Object details

| Category | |

| Object type | |

| Parts | This object consists of 2 parts.

|

| Materials and techniques | Carved and turned walnut, of mortise-and-tenon construction; with rushed drop-in seat of beech, or mortise-and-tenon construction, veneered in walnut at the corners. |

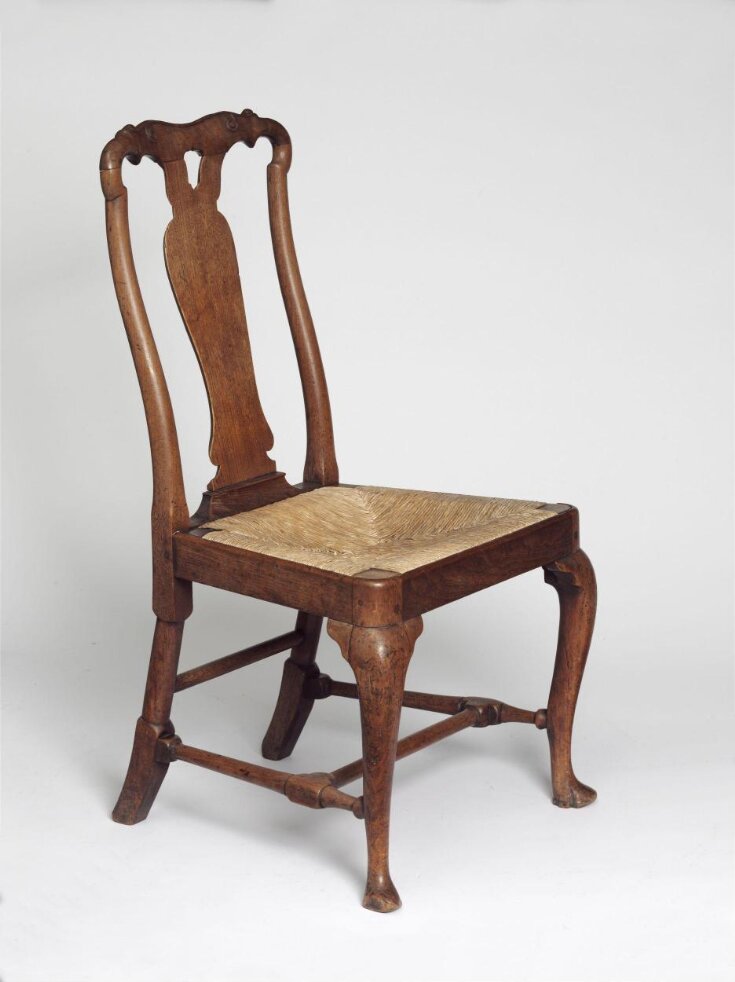

| Brief description | Walnut splat-back chair with rushed drop-in seat, English, 1725-40 |

| Physical description | Design A walnut splat-back chair with drop-in rush seat. The back, of S-shaped ‘bended-back’ profile, has a splat of baluster-shaped outline, pierced at the top. The splat spreads into the serpentine top rail, which is carved in relief with tendrils ending in spiral scrolls. The top rail merges with the crook-shaped tops of the turned, tapering uprights, which are continuous with the raked back legs. At the feet the back legs have a further kick-back, with chamfered edges to reduce their thickness. The canted seat-frame is supported on cabriole front legs, which end in pad feet. Front and back legs are joined by H-form turned stretchers, minimally ornamented, and by a higher, wholly plain back stretcher. The H-form stretchers are shaped in turned sections at the juncture with the front legs, and are left as unturned squared blocks where they join each other and the back legs. The back legs are also squared at this juncture and where they meet the seat, but are turned in between (where they are united by the turned back stretcher). The drop-in seat, flush with the top of the rails, is woven in a conventional pattern, working around the frame from the outside towards the centre. Construction The walnut frame is of mortise-and-tenon construction, partly pegged. The four seat rails are tenoned and pegged to the front legs and the back uprights, the back seat rail extending above the seat in the form of a ‘shoe’. The front and side seat rails, together with the front legs, are rebated to accommodate the drop-in seat. At the back, support for the seat is provided by a walnut batten, nailed (with three nails) to the front face of the back seat rail and the back uprights. The stretchers are tenoned (without pegs) to each other and to the uprights (the lateral stretcher joined to the side stretchers with horizontal tenons, the side stretchers joined to the uprights with vertical tenons). The splat is joined by bare-faced double tenons to the back seat rail (where the tenons are flush at the front) and to the top rail (the tenons flush at the back). The back uprights are tenoned and through-pegged to the top rail. While the other pegs in the frame are roughly square, these ones are rounded in section, perhaps because they are most visible. They are cylindrical, not tapered, for they are of the same diameter at front and back. Some wood has torn out from the inside face of the right seat rail. This could have happened at or soon after the original construction of the chair. In the beech drop-in seat-frame (largely concealed by the rush), the side rails are evidently tenoned to the front and back rails, and the exposed squares at each corner are veneered on top in walnut (the veneer at the back left corner in two joined pieces). On the underside is evidence, presumably, of the method of making the frame, but quite how to interpret this is uncertain: in each corner square is a hole through the thickness of the frame (covered on top by the veneer) and a shallow rectangular dent. The hole, which was probably made from the top (before the top was veneered), may have held a temporary metal(?) peg to tighten the tenon – presumably not a wooden peg, as that would have remained glued into the frame. The shallow dent could perhaps have been made in levering the tool that was used to extract the peg. Rushing The rushes were evidently twisted as they were woven into the seat. Consequently they have a more pronounced twist on the top face than on the underside. Some are Z-twisted, some S-twisted, mostly in clusters mirrored either side of a rather loosely defined middle, but the treatment is not wholly consistent. One knot in the rush is exposed on the underside. Other knots are doubtless concealed. The rush is Grey Club-rush, Schoenoplectus tabernaemontani (C.C. Gmel.) Palla, identified by the Natural History Museum, London. This a more coastal plant than the more commonly used Common Club-rush or Bulrush, Schoenoplectus lacustris (L.) Palla. The drop-in seat frame, numbered (with a chisel-struck roman VIII), is evidently original to the chair. This is an exceptional survival, as the re-rushing of a seat usually involved discarding the frame and making a new one. It may be that the use of a drop-in fame, which needs to fit the chair tightly, led to the retention of the original when (if) it was re-rushed. Although the rush looks very undisturbed, and is clearly of considerable age, it is unlikely that the original rush could have survived for some 250 years before the chair was acquired by the Museum. Condition The walnut is very pale, and has clearly been stripped, perhaps chemically. It was probably sanded down afterwards, as a result of which some originally square corners are now more abraded, and rounded, than could plausibly have been caused by natural wear (for instance on the blocks of the side stretchers). The chair may originally have had a reddish stain (see under Object History). On the seat the walnut veneer is also quite pale, though without the same stripped appearance. The drop-in seat-frame is original, a very unusual survival (see under Rushing). |

| Dimensions |

|

| Gallery label | Chair

About 1725–40

England (probably London)

Walnut, carved and turned

Seat: beech, with some walnut veneer, and grey club-rush (replaced)

Bequeathed by Captain Collingwood Ingram

Museum no. W.49-1981

For centuries, chair seats have been made using rush and sedge. Long, tough plant strands are dampened, hand-twisted and knotted. The continuous cord is then strung around the frame into a four-sided pad.

Although rush is an inexpensive material, ‘matted’ chairs could be fashionable items, as here. The drop-in seat frame makes it easy to replace the rushing.

(01/12/2012) |

| Credit line | Bequeathed by Captain Collingwood Ingram |

| Object history | The history of this chair is unrecorded before 1980 when Captain Collingwood Ingram of The Grange, Benenden, Kent, contacted the Museum offering a bequest. At his death, aged 100, the following year, he bequeathed this chair, a set of six ladder-back chairs, and two other pieces. No account of their previous history was obtained. |

| Historical context | The chair may originally have had a reddish stain, which seems to be implied in the description of 'red framed' chairs in early 18th-century inventories: for instance, a closet at Compton Verney housed '6 Red framed chairs with Dutch Matied Bottoms' ('matting' or 'Dutch matting' was an 18th-century term for rush) (Shakespeare Birthplace Trust, Stratford-upon-Avon: DR98/1743, untitled inventory of Compton Verney, c.1718-28, f. 2v). Ivan Sparkes, in The Windsor Chair (Spurbooks Ltd 1975) p. 116, describes the process of rush matting. 'A much dirtier and unhealthy job [than caning] was the rush matting, the familiar material for use in church seats. The rushes, which came to High Wycombe from the banks of the rivers in nearby Oxfordshire, were dried and arrived in bundles between five and six feet in length. The rush-seat workers sat among the dust and, in order to make the rushes pliable, dampened them with water. This of course added a further hazard to the task. The rushes also gave off a most unpleasant odour, and the saying in Wycombe was that 'you could smell a matter a mile off'.' |

| Summary | Rush seats were common in the 18th and 19th centuries, even for fashionable chairs such as this. Rush was a cheap but visually appealing and comfortable material for a seat. Itinerant rush-makers replaced rush seats when they wore out, but following the decline in this craft, many chairs which were originally rushed have had their rush replaced with upholstery. Rushes grow widely, along river banks and in coastal areas, and were used for basket-making and floor matting as well as seating. For this reason rush chair seat seats were often described as 'matted'. For making chair seats, the long, tough fibres were wetted, then twisted and knotted together to form cords long enough to wrap around the seat frame. Some chairs, such as this example, had a removable seat frame, making re-rushing relatively easy. Rush seats are prone to wear and breakage, so the rush on 18th-century chairs will almost certainly be a later replacement. |

| Collection | |

| Accession number | W.49:2-1981 |

About this object record

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

You can write to us to suggest improvements to the record.

Suggest feedback

You can write to us to suggest improvements to the record.

Suggest feedback

| Record created | November 24, 2005 |

| Record URL |

Download as: JSONIIIF Manifest